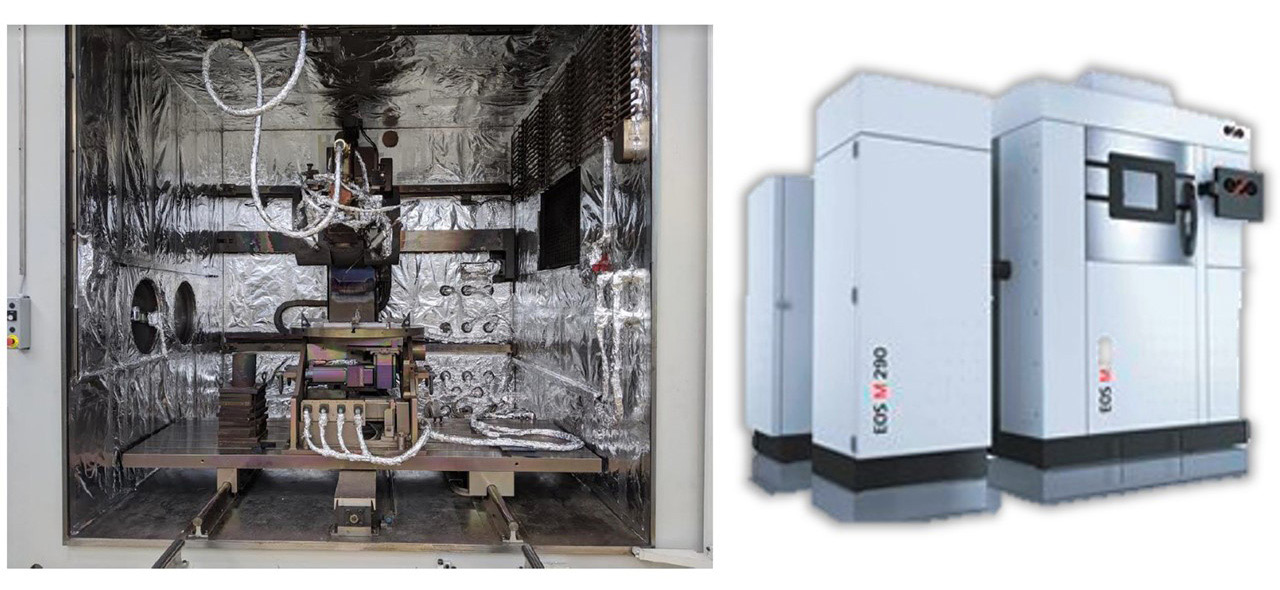

Sciaky EB-DED System and EOS M290 used in production of test samples.

Problem

Additive manufacturing (AM) processes have become increasingly valuable for component production in the naval fleet, but requirements must be established and qualification procedures must be developed. Additional data is required to allow Naval Sea Systems Command (NAVSEA) to develop technical publications for the use of Grade 2 Commercially-Pure Titanium (CP Ti) in Powder Bed Fusion (PBF) and Directed Energy Deposition (DED) AM.

Objective

The objective of this project was to provide NAVSEA with test samples and process qualification test reports (PQTRs) that can be used to develop qualification requirements and procedures for laser PBF (PBF-LB) and electron beam (EB) DED for CP Ti.

Technical Approach

Edison Welding Institute (EWI) was the Principal Investigator for this project effort and produced the following:

- Test samples for corrosion and mechanical properties

- EB-DED coupons with bead orientation according to the test matrix with sufficient machining allowance for no deposited surface exposed upon final specimen extraction.

- Coupons in near-net shape using the PBF-LB process with Grade 2 CP Ti powder.

- Machine near-net-shape coupons from EB-DED and PBF-LB processes to the specimen size.

EWI also provided PQTRs which included technical details such as AM machine configuration, software version, serial numbers, calibration information, build configurations, material certifications, etc.

Accomplishments

- Grade 2 CP Ti test coupons were produced on two AM platforms: EB DED and PBF-LB.

- PBF-LB Equipment: EOS M290

- Laser: Single 400W

- Build volume: 250x250x325mm

- Argon shielding gas

- O2 limit: 0.1%

- Parameters: Titanium

- EB DED Equipment: Sciaky EB DED system (EBAM/EBW VX.3 110x110x110)

- 60 kV at 500 mA (30 kW) 100% Duty Cycle EB Gun

- EBAM IRISS Closed Loop Control (CLC)

- Single Pumping System, PLC Controlled

- Computer Controlled Sequence

- WMMI Interface with CLC Software

- Sciaky Solid State High Voltage Power Supply

- Test coupons were removed from substrates with no further thermal post-processing steps (i.e., in the as-built thermal condition).

- Test coupons were machined via milling, turning and wire EDM, labeled, and inspected.

- PQTRs submitted to the Navy for review.

Project Participants

Project Principal

Other Project Participants

- NCDMM/America Makes

Public Participants

- U.S. Department of Defense