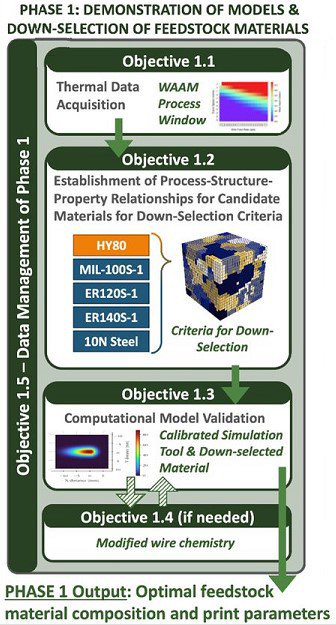

Schematics of the program’s technical approach further broken down into multiple sub-objectives to provide additional details.

Problem

Aging domestic supply chains for cast HY-80 steel leaves the U.S. industrial base at risk of keeping up with future Department of Defense (DoD) demand, causing the need for foreign sources, which presents a high risk for defense applications. Foreign supply chains can be volatile and not subject to U.S. regulations and oversight, hurting warfighter readiness, and raising opportunities for foreign actors to destabilize the U.S. base. Having supply chains in countries whose values are not aligned with U.S. interests could also undermine U.S. foreign policies and impact the economics of domestic steel plants. Thus, the DoD is weakened as the “alarming import surge poses unprecedented threats to the long-term viability of our steel sector, which is vital to our military, preparedness, and disaster response needs.”

Objective

Wire-Arc DED is capable of flexibly printing large parts at high deposition rates; coupled with advanced integrated computational materials engineering (ICME) modeling tools (e.g., thermodynamic, and kinetic modeling, finite element modeling), HY-80 or alternatives can be printed creating more resilient domestic supply chains for Navy orders. This effort’s objective was to demonstrate a qualified data package for HY-80 (or eq.) to S9074-A4-GIB-010/AM-WIRE DED. Phase I objective was to produce down-selected feedback wire material compositions and build parameters. The goals of potential future Phase II work would include further optimization of the material and build process and achieving full-scale procedure demonstration.

Technical Approach

The project team deployed a three-phase process to generate a strategic roadmap that would enable the utilization of AM technologies in the DoD casting and forging supply base. The approach was grounded in strategy methodologies that allowed all stakeholders to understand the challenges of utilizing AM technologies to augment casting and forging supply chain processes. The first phase focused on discovery by identifying the current state while defining a vision for the future state, followed by conducting a prioritized gap assessment between the two. The second phase involved functional analysis of the gaps to identify and prioritize plans to close the gaps. The findings fed a project call that awarded eight projects that began to address the identified gaps. Finally, the third phase was the synthesis of the results which validated the roadmap with critical stakeholders to document the impact of the identified projects and assure execution in the future.

Accomplishments

An ICME approach was implemented combining physics-based modeling and wire-DED experiments under a process-structure-property framework for developing materials and AM processes that can achieve cast HY-80 equivalent properties. Solid wires of four candidate materials (MIL-100S-1, ER120S-1, ER140S-1, and Fe-10Ni) were procured and investigated in this program. Design of experiments with varying printing parameters was conducted and down-selected to find optimal printing parameters to print sample cubes to be sectioned for microstructural characterization. Data was collected as input for finite element thermal profile modeling and thermodynamic microstructure modeling. The blocks were sectioned for microstructure characterization (SEM/EDS, optical microscopy, XRD) and mechanical test (nanoindentation, PIP). The results were used to calibrate and validate the models and process window.

A framework was established to calibrate and validate finite element thermal models for each material using thermophysical properties generated in ThermoCalc software based on the measured wire composition. The thermocouple data and simulated thermal responses showed excellent agreement for each of the materials. The temperature histories were successfully extracted at the desired locations along the build direction for microstructural evolution predictions by WPI and future mechanical property optimization with Solvus. Microstructural characterization of the ER120S-1, ER140S-1, Fe-10Ni wire-DED deposits has shown similar or superior hardness and mechanical performance when compared to wrought HY-80. There is excellent agreement between the predicted and experimental phase analysis results for MIL-100S-1, ER120S-1, ER140S-1 compositions (while Fe-10Ni is all a single phase). Experimental observations related to processing cooling rate changes between layers were also validated by the modeling phase analysis results based upon the thermal modeling work performed by MSU.

ER120S-1 and Fe-10Ni were down-selected, for which additional tensile samples were printed and tested per ASTM E8. The tensile test generated encouraging results, with properties of wire-DED ER120S-1 and Fe-10Ni not far from cast HY-80 targets and met or exceeded in selected metrics. The results also validate the direction and strategy that the team will take in Phase 2 to achieve 100% of HY-80 performance and the ultimate program goal of qualifying and transitioning the material and wire-DED process.

Project Participants

Project Principal

Other Project Participants

- Solvus Global

- Mississippi State University (MSU)

Public Participants

- U.S. Department of Defense