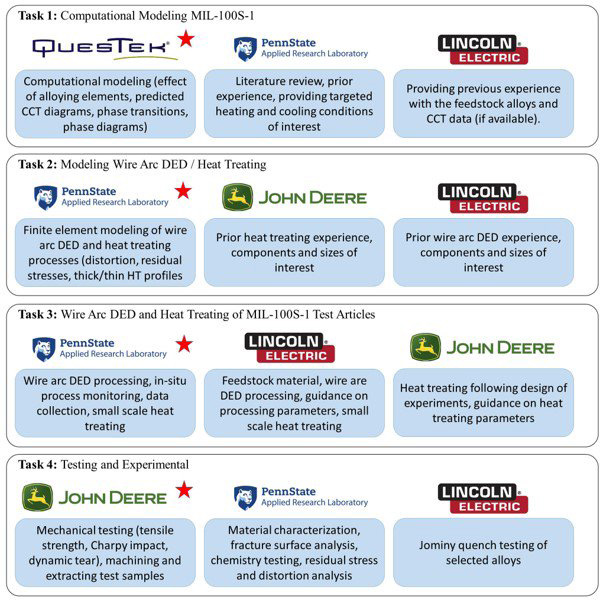

Pictorial representation of the project’s technical plan including descriptions of project responsibilities for each organization.

Problem

Commercially available feedstocks often used for wire-arc DED are not designed to serve as bulk material and therefore may not perform similarly to the original cast materials. Although post-build heat treating is desired to promote homogeneity, residual stress reduction, and the relaxation of interpass temperature constraints typically required for welding, standardized heat treatment procedures for commercially available wire-arc DED feedstocks do not exist.

Objective

The objective of this effort was to develop and demonstrate optimized wire-arc directed energy deposition (DED) process and post-process heat-treating procedures to replace HY-80 steel castings. This was achieved by compiling available program data, determining and reviewing process and property relationships, and completing elemental refinement modeling for MIL-100S-1.

Technical Approach

The first task under this project was to perform MIL-100S-1 alloy computational modeling to identify equilibrium, non-equilibrium phases, and phase transformation temperatures to inform the optimum wire-arc DED processing conditions and post-heat-treating conditions. This task also investigated optimum chemistries within the MIL-100S-1 specification to reduce the quenching sensitivity for uniform properties between thick and thin sections. The second task involved wire-arc DED process thermomechanical modeling to improve optimum build path understanding, assuring in-process heating was maintained at acceptable levels to minimize distortion. This task also modeled the heat-treating response to understand expected heating and quenching curves as a function of distance from the surface. With the information gained from tasks one and two, task three produced builds by wire-arc DED and these builds were sectioned for heat-treating evaluations. Lastly, task four conducted a material characterization on samples to assess the impact of various wire-arc DED processing and heat-treating conditions used.

Accomplishments

The Pennsylvania State University Applied Research Laboratory (PSU ARL) team demonstrated that-wire-arc DED using a MIL-100S-1 feedstock material can be used to produce large HY-80 casting replacements. They produced a large wire-arc DED build weighing approximately 500 pounds (lbs) that easily exceeded both tensile and Charpy impact testing minimums for HY-80 castings. Their efforts showed there are two main strategies for producing large wire-arc DED components using MIL-100S-1 for HY-80 casting replacement. The first strategy used a low interpass temperature (IPT) of 300°F (149°C) to ensure that each weld pass exhibited fast cooling rates during deposition. Subsequent re-austenitizing of the deposited material was not needed. Instead, tempering of each layer was conducted in-process through auto-tempering as subsequent layers deposited re-heat the layers below. The advantage of this approach was that the low hardenability of the MIL-100S-1 alloy did not limit the component size envelope. Subsequently, components can be produced with this processing strategy that are on the meters size scale.

The second strategy relied on post-process austenitizing with quenching to ensure that the deposited material achieved a martensitic structure that could be tempered for adequate strengths and impact toughness. The advantage of this strategy was that the wire-arc DED process could be conducted without strict IPT controls. In the as-built state, the tensile strengths and impact toughness values were low, but after re-austenitizing and quenching, the resulting strengths and impact toughness values exceeded HY-80 casting minimums. This opened the ability to quickly produce certain components with the MIL-100S-1 alloy with minimal machine stops and also opened the door to multi-head processing. However, this strategy has a drawback due to the poor hardenability of this alloy, which limits the size envelope for a component to a block with a thickness of 5” (127mm). If quenched fast enough after post-process austenitizing, both tensile and Charpy impact values measured from this block easily exceeded HY-80 requirements.

Project Participants

Project Principal

Other Project Participants

- John Deere

- Lincoln Electric

- Questek

Public Participants

- U.S. Department of Defense