Novel approaches for integrated thermally managed sharp leading-edge solutions to provide application across various high-temperature platforms.

Problem

There is an increased need for novel techniques to manufacture leading edges for high speed flight systems. This includes thermal management for the edges while maintaining shape stability. Additionally, a well-trained high-temperature applications workforce is essential to support the development of all aspects of high temperature weapon systems.

The aging Aerospace & Defense Workforce (A&D) and the lack of supply of fresh domestic talents now critically endanger workforce sustainability.

Objective

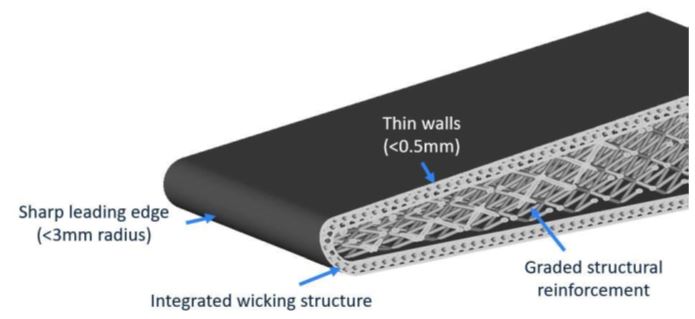

The project aims to develop an integrated thermal management solution for high heat flux tolerant leading-edge designs that are broadly applicable to different high-temperature platforms. The proposed semi-passive cooling approach and refractory alloy components for thermal management will enable the fabrication of structures that tolerate the high heat flux (>1000 sq cm) scenarios required for prolonged exposure. In addition, to support the U.S. industry, government, and academia in providing educational training leading to a highly skilled workforce essential to support the development of all aspects of high-temperature weapon systems, the Digital Engineering Aerospace Systems Design Center will be established in Huntsville, AL (DEDC@Huntsville).

Technical Approach

The University of Texas at El Paso (UTEP) will leverage the experience within its Aerospace Center also known as cSETR along with the UTEP W.M. Keck Center for 3D Innovation to develop representative system requirements definition and integrated system modeling for thermally managed thin and sharp leading-edge applications to benefit U.S. high-temperature platforms. The team will build additive manufacturing (AM) structures of leading-edge and engineered heat pip structures or other semi-passive structures from the developed requirements. The team will perform experimental characterization of thermal performance for these AM structures. In addition to the thermal performance of the structures, research will be done to investigate the attachment of the leading-edge structures that may be of a different material than the structure to which it will be attached. This will include the evaluation for producing graded materials to facilitate leading-edge attachment and mitigation of material degradation from oxidation at operating conditions. In addition to the technical tasking occurring, UTEP will address the aging Aerospace & Defense Workforce and lack of fresh domestic talents by establishing a project-based digital engineering/design center in Huntsville, AL. Training of 24 high-temperature talents with extensive engineering skills will occur during the two-year project.

Project Participants

Project Principal

Other Project Participants

Public Participants

- U.S. Department of Defense