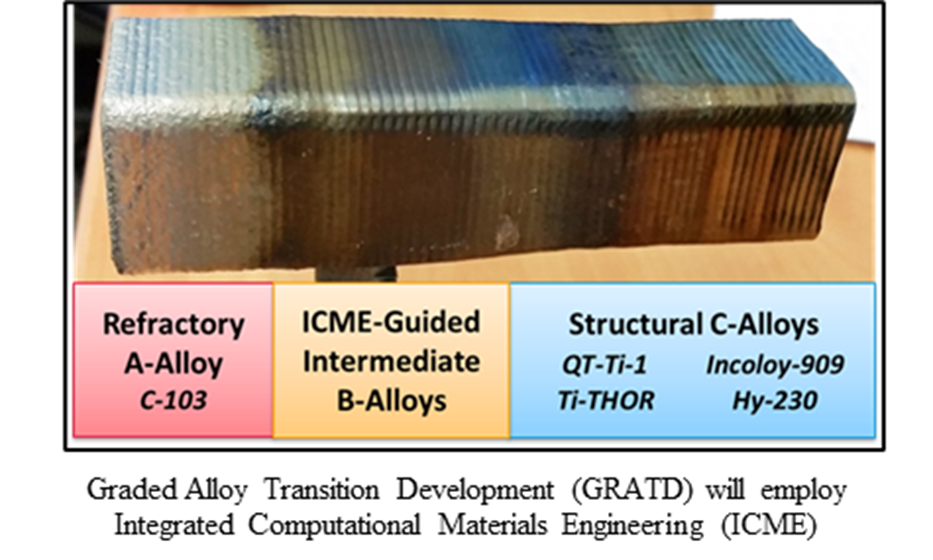

Graded Alloy Transition Development (GRATD) employs Integrated Computational Materials Engineering (ICME).

Problem

Additive manufacturing (AM) is a valuable enabler for rapidly manufacturing complex assemblies. The Office of the Under Secretary of Research and Engineering’s (OUSD R&E) Technology & Manufacturing Industrial Base in collaboration with the Assistant Director, Hypersonics has identified the development of AM for high-temperature metals as key to timely fielding of high-mach capabilities, addressing shortfalls of traditional manufacturing processes which are often costly, low-yield, and labor intensive. Additionally, aero-thermal environments experienced by hypersonic vehicles require joining dissimilar materials to reduce weight and increase thermal/structural performance. Developments in AM techniques for processing high-temperature and dissimilar material sets for high-mach applications are needed to exploit the advantages of AM.

Objective

This program aimed to develop graded alloy transitions for high-mach systems by demonstrating and validating the ability of AM techniques to achieve higher joint performance for a relevant material set compared to baseline processing/bonding method(s). This project sought to combine Boeing’s high-mach design knowledge and AM experience, QuesTek’s state-of-the-art integrated computational materials engineering (ICME) tools, and RPM Innovations proven powder feed direct energy deposition (DED) procedures and build parameters to develop additive-enabled leading and control fin edge transition joints.

Technical Approach

The GRaded Alloy Transition Development (GRATD) project involved four primary tasks:

- Identifying and down-selecting graded materials and using ICME tools to perform equilibrium and non-equilibrium (Scheil) thermodynamic calculations at various compositions along the gradient to assess potential formation of undesirable phases (i.e. brittle intermetallic phases) during solidification, thermal exposure, or heat treatment.

- Developing the transition process(s) and determining the base alloy properties.

- Characterizing the graded transition interface and properties.

- Delivering a final report including all project results, conclusions, and recommendations.

Accomplishments

This project demonstrated the feasibility of using blown metal powder, Laser-Directed Energy Deposition (L-DED) Additive Manufacturing (AM) to deposit functionally-graded structural transitions between C103 niobium (Nb) alloy (niobium-hafnium-titanium [Nb-Hf-Ti]) and three (3) different Ti alloys – Titan-23, QuesTek-Ti, and Ti-6242. Key results, conclusions, and future activities are:

- Graded transitions from C103 to Ti-alloys worked well, although concerns with hot cracking susceptibility required avoiding certain mixture ratios.

- Wall builds and tensile testing transitioned C103 to Titan-23, QuesTek-Ti-1A and Ti-6242 materials.

- Room temperature tensile tests confirmed failures in the weaker C103 region.

- Vacuum heat-treating Ti-alloys did not cause embrittlement or other issues in transition regions.

- Graded Transitions from C103 to Ni alloys (Hy-25, Hy-230, and Incoloy-909) were unsuccessful.

- Integrated Computational Material Engineering predicted challenges, i.e., the formation of intermetallics and brittle phases.

- Commercially-pure Vanadium (CP-V) worked well to transition away from C103 with Nb and Hf.

- Transition from CP-V to Ni-based alloys was not successful.

- Deposition of a secondary transition from CP-V to Chromium (Cr) was successful, and was predicted to possibly facilitate Hy-25 transition.

- Cracks occurred when attempting 80w% Chromium (Cr) /20w% Hy-25 deposition on a Cr layer.

Project Participants

Project Principal

Other Project Participants

- RPM Innovations, Inc.

- QuesTek Innovations, LLC

Public Participants

- U.S. Department of Defense