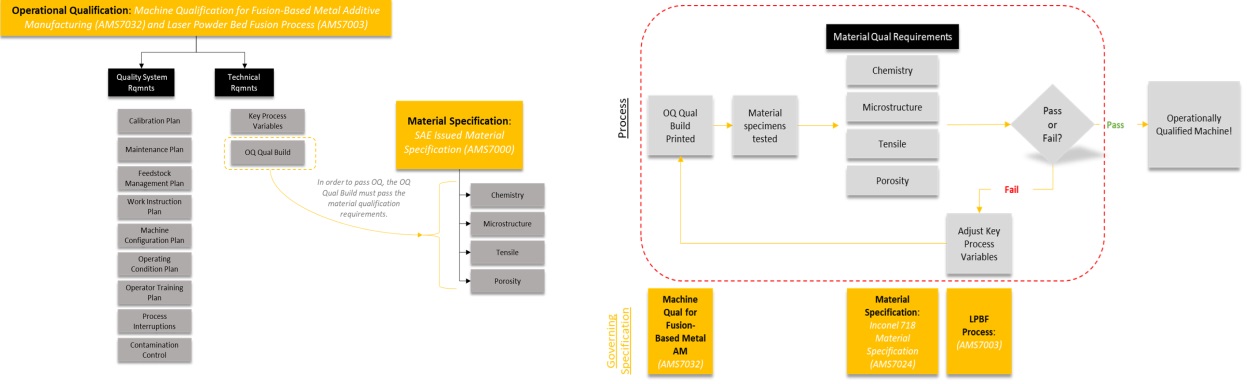

Graphic representations for operational guidance development and key process variable (KPV) window studies.

Problem

Operation qualification (OQ) is a myriad of tasks that leads to process control documentation substantiated through characterization, analysis, and testing to confirm the process can deliver to material requirements. Specific barriers to rapid OQ to be addressed in this program include the lack of clear requirements and checklists for manufacturers of additively manufactured (AM) parts, lack of guidance and key process variable (KPV) relationships to OQ requirements, lack of OQ auditing and approval agencies, and lack of industry demonstration and acceptance of means of compliance to OQ.

Objective

Wichita State University National Institute for Aviation Research (WSU NIAR) has composed a program that will establish a sustainable OQ process to be widely implemented within the organic and defense industrial bases (OIB and DIB). This will allow for a shorter and less costly process which will accelerate our nation’s conversion from an AM capability to a capable AM manufacturing capacity. NIAR will deliver a public framework that outlines OQ requirements including material specifications, a published KPV window study to aid in material specification compliance, and an industry verification process.

Technical Approach

WSU NIAR will address four specific barriers to rapid OQ within the OIB and DIB. To overcome those barriers, an industry advisory board will assist by sharing lessons learned and guiding the work scope. To address the first barrier, “Lack of clear requirements and checklists for AM part manufacturers,” WSU NIAR will partner with the Society of Automotive Engineers (SAE) International and National Aerospace and Defense Contractors Accreditation Program (Nadcap). This task will focus on integrating the OQ requirements detailed within AMS7032 and AMS7003 into its audit program or within Nadcap’s existing AC7110/14 audit program. This will provide clear, standardized requirements and checklists for AM part suppliers to reference as they work to achieve an operationally qualified shop. Leveraging the guidance document and checklist developed in the preceding task, Nadcap will develop an accreditation specific to OQ for LPBFAM. This accreditation will address the “Lack of OQ auditing and approval agencies” and provide both industry and suppliers with an informed, trained, and experienced auditing and accreditation agency. To address the “Lack of clear guidance and KPV relationship to OQ requirements,” NIAR will execute a window study analysis that compares the correlations, or lack thereof, between the “KPV required for LPBF Process” of AMS7003 and “LPBF process specification” as well as the material qualifications requirements listed within the appropriate material specifications of AMS7000. The final barrier this team will address is the “Lack of industry demonstration and acceptance of means compliance to OQ.” This will be accomplished with the help of an ASTRO America-identified small to medium-sized business supplier (SMB), Sintavia. Sintavia will implement deliverables from phase one and prepare for an OQ audit by Nadcap and the National Center for Advanced Materials Performance (NCAMP) officials using the guidance documents generated under this scope of work.

Project Participants

Project Principal

Other Project Participants

- REACT Lab Tinker Air Force Base

Public Participants

- U.S. Department of Defense