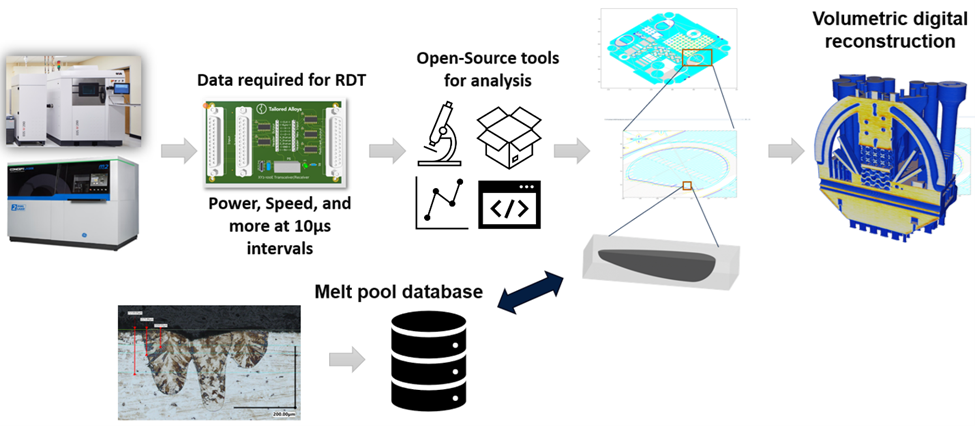

The figure illustrates an example workflow based on the Reproducible Digital Thread where hardware and software tools are used in conjunction with a melt pool database to generate a holistic digital review of a build.

Problem

The Department of Defense (DoD), NASA, and standards organizations have joint and siloed efforts in additive manufacturing (AM) with universally identified gaps in AM-specific technical data package requirements, materials design allowables, cybersecurity, data management, workforce development, and qualification/certification. Numerous projects have attempted to address these well-documented gaps, yet the same fundamental problem remains; there is not an accepted approach to materials property data to design or validate against. No unified and realistic effort will succeed while the melt strategy in laser powder bed fusion (LPBF) AM, as a frontier example, is partially obscured or hidden by the LPBF equipment manufacturers. This leads to the conclusion that all efforts currently focused on establishing materials databases for LPBF AM are fundamentally flawed due to the usage of machine-specific blackbox parameters that are not possible to repeat. The Trusted Metal approach will solve this problem with a common machine-agnostic reproducible digital thread (RDT) that is open and available to the U.S. Government for action, benefit, and utilization.

Objective

The overarching objective is to unify the metal AM industry through the development and demonstration of an RDT and associated open-source analysis tools. Trusted Metal will develop an RDT capable of direct integration with original equipment manufacturers (OEMs) and a bolt-on solution capable of aftermarket integration. The RDT will be demonstrated on multiple machines in multiple facilities throughout the project.

Technical Approach

Trusted Metal will undertake five primary tasks to develop and demonstrate the RDT for the LPBF AM process. They will leverage their subject matter expert network and evaluate the current state of RDT research to develop a report of minimum viable product requirements and an implementation plan for the RDT. Next, the team will establish the Center for Trusted Metal Manufacturing (CTMM) to provide a physical location to generate test data and evaluate the RDT. Additionally, a metal pool database will be developed as a standard resource for comparison to the RDT and to assist in determining build conformance.

In parallel with the efforts at CTMM, Trusted Metal will engage with OEMs to develop an integration and implementation strategy for the RDT in LPBF. After completing the RDT demonstration at CTMM, Trusted Metal will travel to multiple DoD locations to demonstrate the RDT on several makes and models of LPBF machines at multiple facilities. Finally, Trusted Metal will provide training to the DoD on the implementation and use of the RDT and sourcing quality of LPBF parts.

Project Participants

Project Principal

Other Project Participants

- NCDMM/America Makes

- Air Force Research Laboratory

Public Participants

- U.S. Department of Defense