Project work is divided into three phases, culminating in the creation of a functional TEA tool.

Problem

There are instances where additive manufacturing (AM) can serve as a method to bridge gaps in component sourcing for casting and forging applications. However, these applications and opportunities lack definition and understanding. In addition, the economics of technology transition from casting and forging to AM have often failed to demonstrate a comprehensive return on investment (ROI) at the macroeconomic level. To truly understand the economics of transitioning from casting and forging to AM, a techno-economic analysis (TEA) framework is required. A preliminary analysis of product types, considerations, and acceptance standards in concert with an AM technology/manufacturing readiness assessment is needed to develop such a framework.

Objective

The objective of this project is to create a tool that provides a TEA framework for when, where, and how to utilize AM technologies to bridge gaps in component sourcing. This tool will cover four metal AM modalities: Laser powder bed fusion (PBF-LB), laser and electron beam directed energy deposition (DED), wire arc additive manufacturing (WAAM), and additive friction stir deposition (AFSD). The tool should provide insight as to why traditional cost models show that AM is more expensive than traditional castings and forgings and whether this will continue to be true as the AM industry matures.

Technical Approach

Wichita State University National Institute for Aviation Research (WSU NIAR) will create a TEA framework to enable the application of four additive manufacturing modalities to bridge the current casting and forging manufacturing methods.

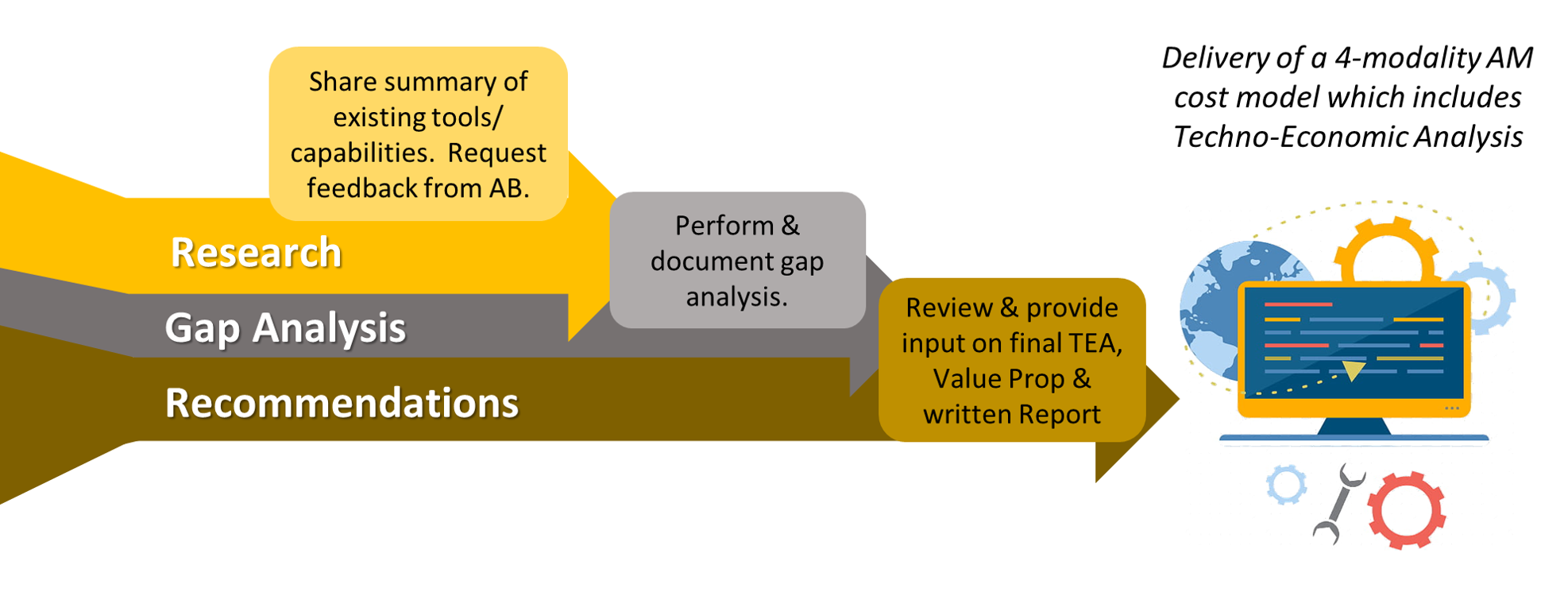

Work will be divided into three sequential milestone efforts: research, gap analysis, and recommendations. These work streams will in turn focus on three topic areas – TEA, technical AM, and the sourcing process – to ensure the delivered framework can be leveraged across the sustainment lifecycle process. Throughout the project, an advisory board composed of government agencies and industry stakeholders with expertise in the above three focus areas will provide input.

During the research phase, WSU NIAR will seek, review, and compare existing AM cost tools including recommendations from the advisory board. These models will then undergo a gap analysis focusing on their accuracy within techno-economic viability, technical AM precision, and sourcing application. The final phase of the program will be the creation of a TEA framework that provides the tools needed to make informed decisions concerning all relevant factors.

Project Participants

Project Principal

Other Project Participants

- Valdos Consulting, LLC

Public Participants

- U.S. Department of Defense