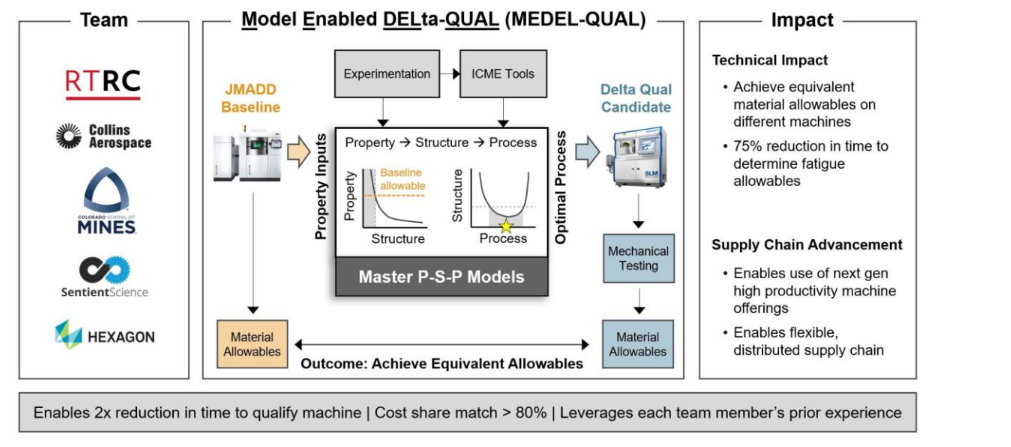

This graphic illustrates the technical approach and impact of the RTRC MEDEL-QUAL project.

Problem

Additive manufacturing (AM) machines and materials qualification are major barriers to broad AM adoption. Generating the requisite data and models requires significant resources to produce statistically significant data. This qualification process requires generating test coupons under a controlled process and testing and analysis of the resulting data. These processes are then “frozen” with no changes to key process variables allowed. Standard-based guidance does not exist for requirements when a process change is needed. This greatly inhibits the agility of AM processes to respond to changes in the technology or supply base, allowing only one path to implement change to a qualified process — a total requalification, which may cost more than $3M per machine/material combination and take several years.

Objective

The MEDEL-QUAL team will develop and demonstrate a delta qualification methodology that utilizes advanced empirical, analytical, and numerical tools to model the process-microstructure-property relationships of Ti-6Al-4V additively built material to an SLM280 machine against a baseline material data set generated under Joint Metal Additive Database Definition (JMADD) on EOS M290 machines. Additionally, the proposed program will utilize the resulting data sets to validate the use of Integrated Computational Materials Engineering (ICME) tools to reduce the time required to generate fatigue allowables by 75%.

Technical Approach

RTX Technologies Research Center (RTRC) will generate an Initial Experimentation (IE) test plan and build-to-print Ti-6Al-4V specimens using an SLM 280 machine. Mechanical properties from these builds will be analyzed to develop an initial process-structure-property model for the subsequent delta qualification builds. The mechanical analysis of the IE builds will assist in defining the optimum machine parameters for the delta qualification test plan. RTRC will produce up to 120 Ti-6Al-4V specimens built in accordance with the test plan and then complete mechanical property testing and Scanning Electron Microscopy (SEM) fractography to generate mechanical property curves consistent with a statistically based mechanical properties curve (B-Basis). Results from the delta qualification will be compared against the baseline JMADD results to determine equivalency. RTRC will also refine the process-structure-property model developed with the IE builds after completing the delta qualification builds.

Project Participants

Project Principal

Other Project Participants

- Collins Applied Research & Technology

- Colorado School of Mines

- Hexagon Manufacturing Intelligence

- Sentient Science

Public Participants

- U.S. Department of Defense