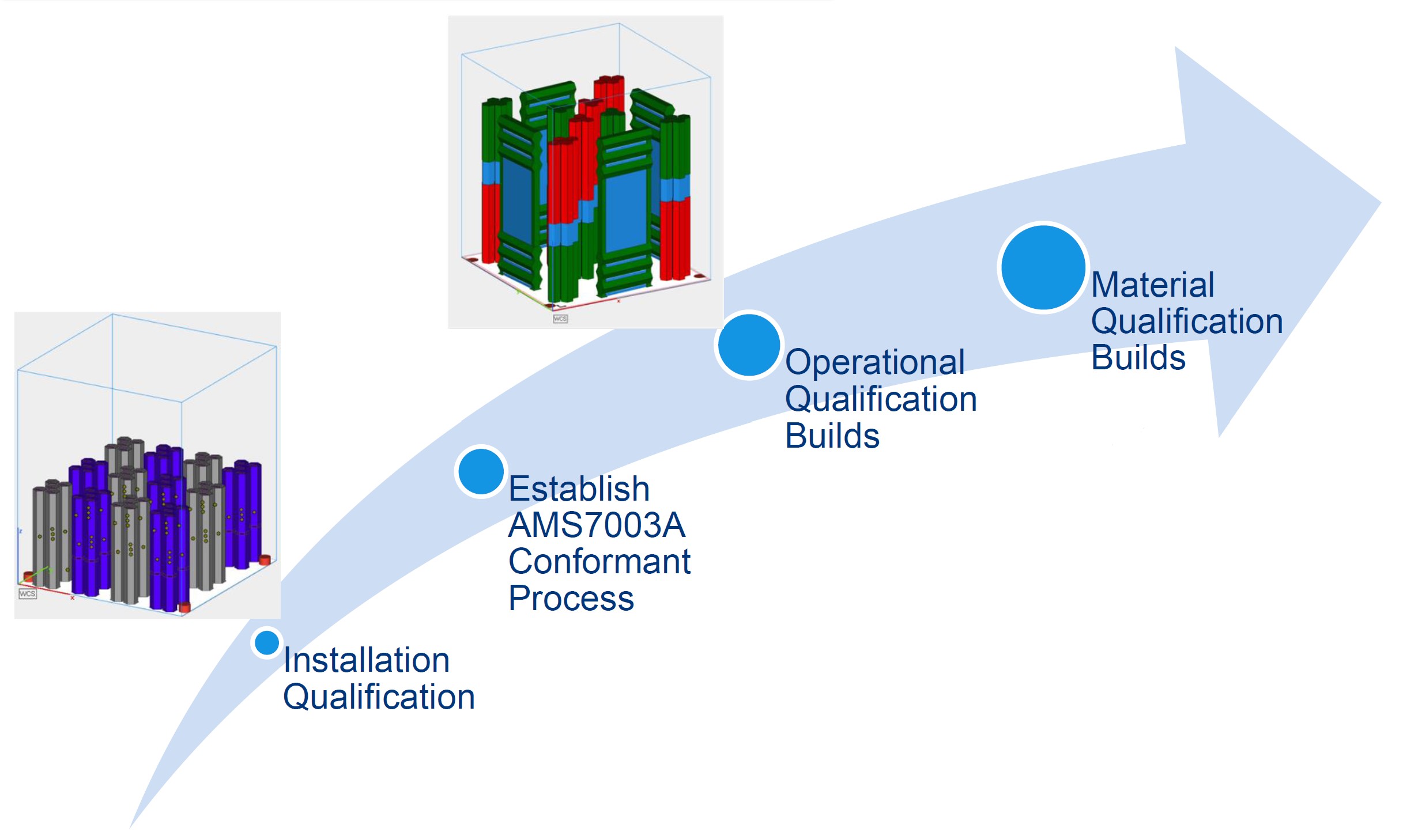

Installation Qualification (IQ), Operational Qualification (OQ), and Material Qualification (MQ) activities will be completed on each of the two laser powder bed fusion (LPBF) printers.

Problem

Additive manufacturing (AM) machines and materials qualification are major barriers to broad AM adoption. Generating the requisite data and models requires significant resources to produce statistically significant data. This qualification process requires generating test coupons under a controlled process and testing and analysis of the resulting data. These processes are then “frozen” with no changes to key process variables allowed. Standard-based guidance does not exist for requirements when a process change is needed. This greatly inhibits the agility of AM processes to respond to changes in the technology or supply base, allowing only one path to implement change to a qualified process — a total requalification, which may cost more than $3M per machine/material combination and take several years.

Objective

The primary objective of this project is to establish a baseline for the effort needed to qualify a machine at a vendor for laser powder bed fusion (LPBF), and then demonstrate the process required to bridge this qualification to a different machine.

An additional goal of the project is to qualify two vendors to produce aerospace-quality parts from Ti-6Al-4V based on an accepted industry specification. This will allow Boeing, the Air Force, and any other organization to use these vendors to produce parts.

Technical Approach

Building on their knowledge and experience with the EOS M290, Boeing will establish a Process Control Document (PCD) to conduct Installation Qualification (IQ) Operational Qualification (OQ), and Material Qualification (MQ) for an M290 located at Beehive Industries. These qualification activities will follow the Aerospace Material Specification (AMS)7032 framework and the process control approach defined in AMS7003A.

Boeing will then apply the same qualification methodology to a Renishaw 500Q at Innovative 3D. Due to the differences in machine design, including the differing number of lasers, this machine will require more initial analysis for IQ and OQ.

Upon completion of this project, there will be clear documentation regarding the methods for qualifying a vendor to an industry specification for producing Ti-6Al-4V material using LBPF. There will also be documentation regarding the effort required to qualify a vendor for a different machine (bridge qualification) that is not well-known to the original equipment manufacturer (Boeing). This documentation will be provided to other organizations that will be working concurrently to develop innovative methods to reduce the level of effort required to conduct a bridge qualification.

Project Participants

Project Principal

Other Project Participants

- Beehive Industries

- Innovative 3D

Public Participants

- U.S. Department of Defense