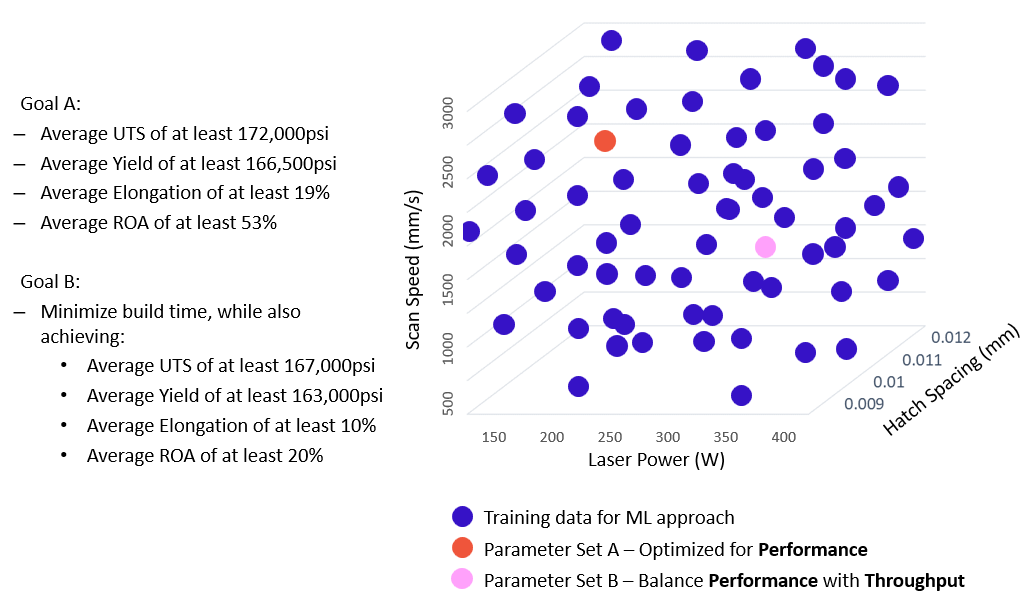

The illustration demonstrates the machine learning approach that will be used on the project to leverage training data to develop parameter sets.

Problem

Additive manufacturing (AM) machines and materials qualification are major barriers to broad AM adoption. Generating the requisite data and models requires significant resources to produce statistically significant data. This qualification process requires generating test coupons under a controlled process and testing and analysis of the resulting data. These processes are then “frozen” with no changes to key process variables allowed. There is no standard-based guidance for what is required when a change to the process is needed. This greatly inhibits the agility of AM processes to respond to changes in the technology or supply base, allowing only one path to implement change to a qualified process — a total requalification, which may cost more than $3M per machine / material combination and take several years.

Objective

This project will demonstrate an approach to AM allowables and delta qualifications that leverages AM’s digital nature with machine learning (ML). ML has successfully demonstrated effectiveness across other industries for its flexibility and capacity to withstand AM process changes (e.g. changing AM material or machine), making this approach ideal for long-term sustainment.

Technical Approach

Senvol will complete three significant tasks: generating data, analyzing the data using the ML approach, and conducting validation builds to confirm equivalency to achieve a minimum equivalence to the Joint Metal Additive Definition Database (JMADD) program material baseline. Project training data will be generated through two separate builds on an EOS M400-1 machine, followed by mechanical testing of the specimens. Once data is collected, Senvol will use its ML software to quantify the relationship between machine parameters and mechanical performance to calculate machine learning allowables. Specifically, Senvol will develop one machine parameter set for the EOS M400-1 that will meet all baseline JMADD mechanical performance requirements and calculate the B-Basis machine learning allowable for each mechanical property target using the model generated by the machine learning software. Lastly, the Senvol team will create additional builds on the EOS M400-1 using the machine parameters developed in the previous task to evaluate the mechanical results of those builds using the AMS 7032, National Institute for Aviation Research (NIAR), and National Center for Advanced Materials Performance (NCAMP) qualification approaches to determine equivalence to the baseline JMADD data set.

Project Participants

Project Principal

Other Project Participants

- 3Degrees

- AoZora Additive

- ATI

- Battelle

- Boeing

- Element

- National Institute for Aviation Research (NIAR)

- Pilgrim Consulting

Public Participants

- U.S. Department of Defense