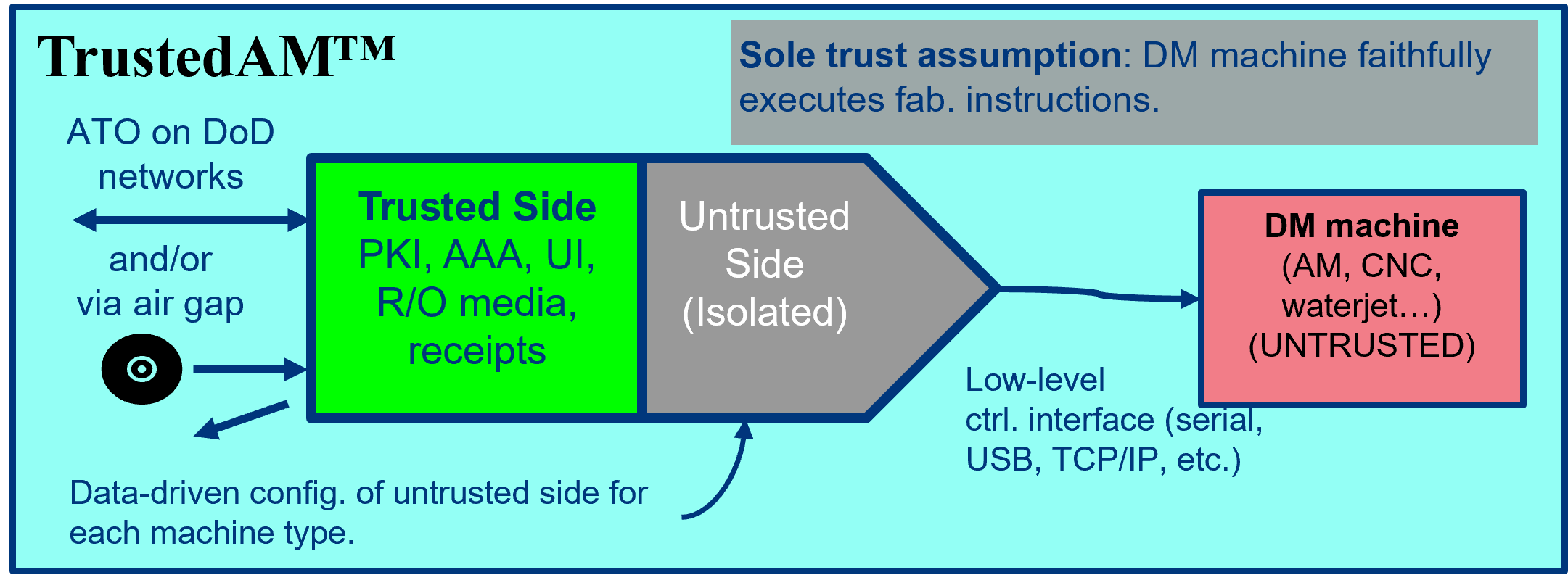

TrustedAM™ establishes trust in devices connecting to resources containing sensitive information

Problem

Additive manufacturing (AM) machines are problematic from a cybersecurity standpoint. They typically contain sophisticated computer systems designed for industrial/commercial deployment but do not meet the rigorous certifications required for authority to operate (ATO) on Department of Defense (DoD) networks and are generally not trusted. As a result, most AM machines are “air-gapped” from DoD networks, and AM artifacts are transported via read-only media (such as CD-ROMs). The process itself is cumbersome and inconvenient for the user compared to, for example, the user clicking “print” in a web portal and printing the part on any (authorized) machine similar to networked printers.

Objective

The goal of the project was to provide a means for AM machines in the DoD to connect to an IT system using an encrypted secure digital device without having to qualify or certify via ATO/RMF (risk management framework) every AM machine in the DoD’s inventory. TrustedAM™ provides secure transactional integrity across air gaps and enables key digital twin functionality and process and policy controls, including support for third-party intellectual property. This project sought to utilize the TrustedAM™ Mark I trusted endpoint, which is a hardened, embedded system that provides trusted connectivity between the repository and the AM machine. These endpoints are available off the shelf and are being adapted for DoD use.

Technical Approach

AURA Technologies selected two AM machines from a list of 10 candidates provided by the government to install trusted endpoints and perform assessment testing. The next step was to configure, deliver, and install two COTS-trusted endpoints at an Army facility and two COTS-trusted endpoints at a USMC facility. AURA conducted interoperability and integration testing and assessments of the COTS-trusted endpoint with each selected AM machine. The company provided a one-year limited warranty on Mark I trusted endpoint hardware, as well as remote technical support and firmware and software maintenance throughout the project duration.

Accomplishments

AURA Technologies delivered and installed trusted endpoints on five additive machines at four government sites. In addition to proving the endpoints’ effectiveness on AM machines, the team was able to demonstrate their effectiveness on a CNC system. The additive machines that were leveraged were the MarkForged X7, Formlabs 3L, MarkForged Mark 2, and HP 4200 3D Jet Fusion. The CNC machine was the Phillips Hybrid/UMC 750. The TrustedAM Software Client (TSC) was also implemented at each of the sites to send build jobs securely to networked machines and digitally verify that fabrication had been completed. Interoperability and integration testing were completed successfully at each site. Validation of success was obtained by fabricating at least one part by submission of a fabrication request from the TSC to a trusted endpoint connected to one of the down-selected machines. This project was a crucial step for AURA and its TrustedAM™ system as it has served as a bridge to commercialization, and more importantly, into the hands of warfighters and their civilian colleagues in the Organic Industrial Base (OIB).

Project Participants

Project Principal

Other Project Participants

- AURA Technologies

Public Participants

- U.S. Department of Defense