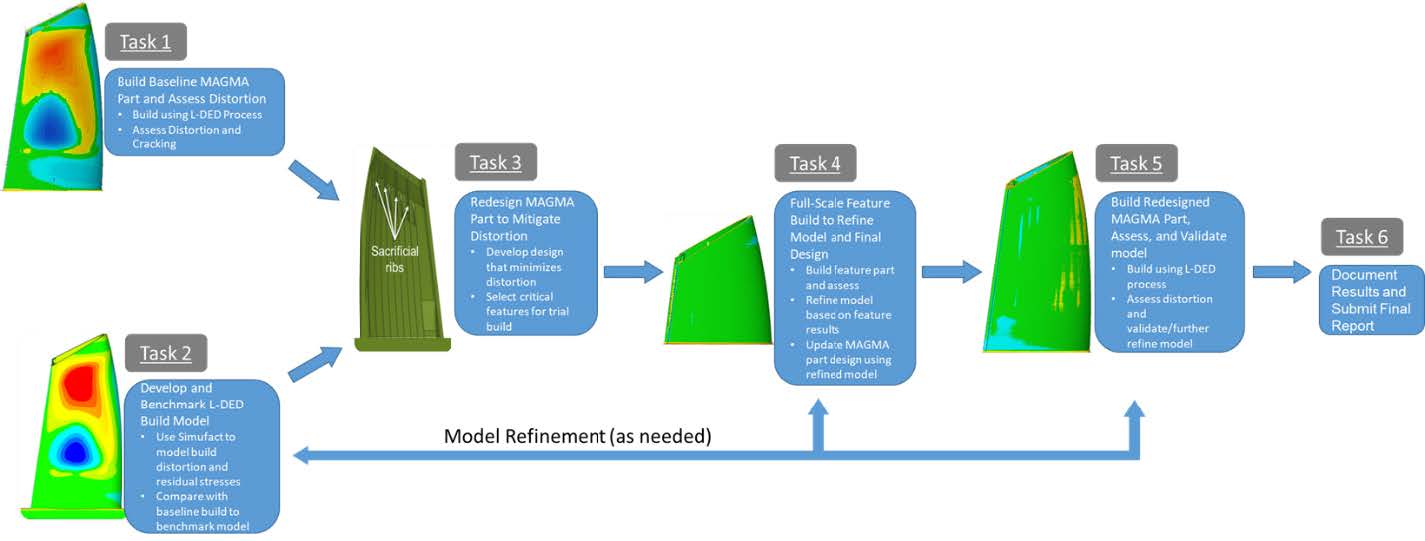

Program flow chart with anticipated model refinement iterations

Problem

To meet the extreme aero-thermal environments experienced by high-speed vehicles, super alloys are being investigated in conjunction with additive manufacturing (AM) to create complex vehicle geometries. Due to schedules and budgets, it is crucial to achieve first-time quality parts. However, the steep thermal gradients experienced during the laser directed energy deposition (L-DED) process can adversely affect the geometry by inducing distortions through residual stress buildup, causing it to fail geometric tolerancing design requirements.

Objective

The goal is to leverage extensive high temperature design knowledge and AM experience of Boeing, state-of the-art simulation tools of Hexagon, and proven powder feed L-DED procedures and deposition parameters of RPM Innovation (RPMI) to develop a physics-based build simulation model for the L-DED process to predict distortions in Inconel 718 parts before they occur in the manufacturing process. This capability enables the industry to assess a new design before attempting a build, thus eliminating costly build iterations.

Technical Approach

This project involves six technical tasks. In Task 1, RPMI will additively manufacture a Maturation of Additive Geometric Management Approaches (MAGMA) part via L-DED. This task will compare post-build distortional measurements to the as-designed computer-aided design (CAD) model. Task 2 will run concurrently with Task 1 and predict distortions in the as built MAGMA part. The analysis results will be compared to the as-built measured distortions. Also, in Task 2, the prediction model will be updated to best correlate to the as-built. In Task 3, the MAGMA part will be redesigned to mitigate distortion with an updated prediction for comparison to the as-designed model. In Task 4, feature based builds will be performed on key design features of the MAGMA part. The updated L-DED simulation process will be applied to these feature builds and further refinement of the L-DED simulation will occur. In Task 5, RPMI will build a final MAGMA part with the improved features and design. The build simulation model will be run concurrently and a final comparison of measured (as-built vs predicted) will be performed. In Task 6, all results will be documented into a final report.

Project Participants

Project Principal

Other Project Participants

- RPM Innovations, Inc.

- Hexagon

Public Participants

- U.S. Department of Defense