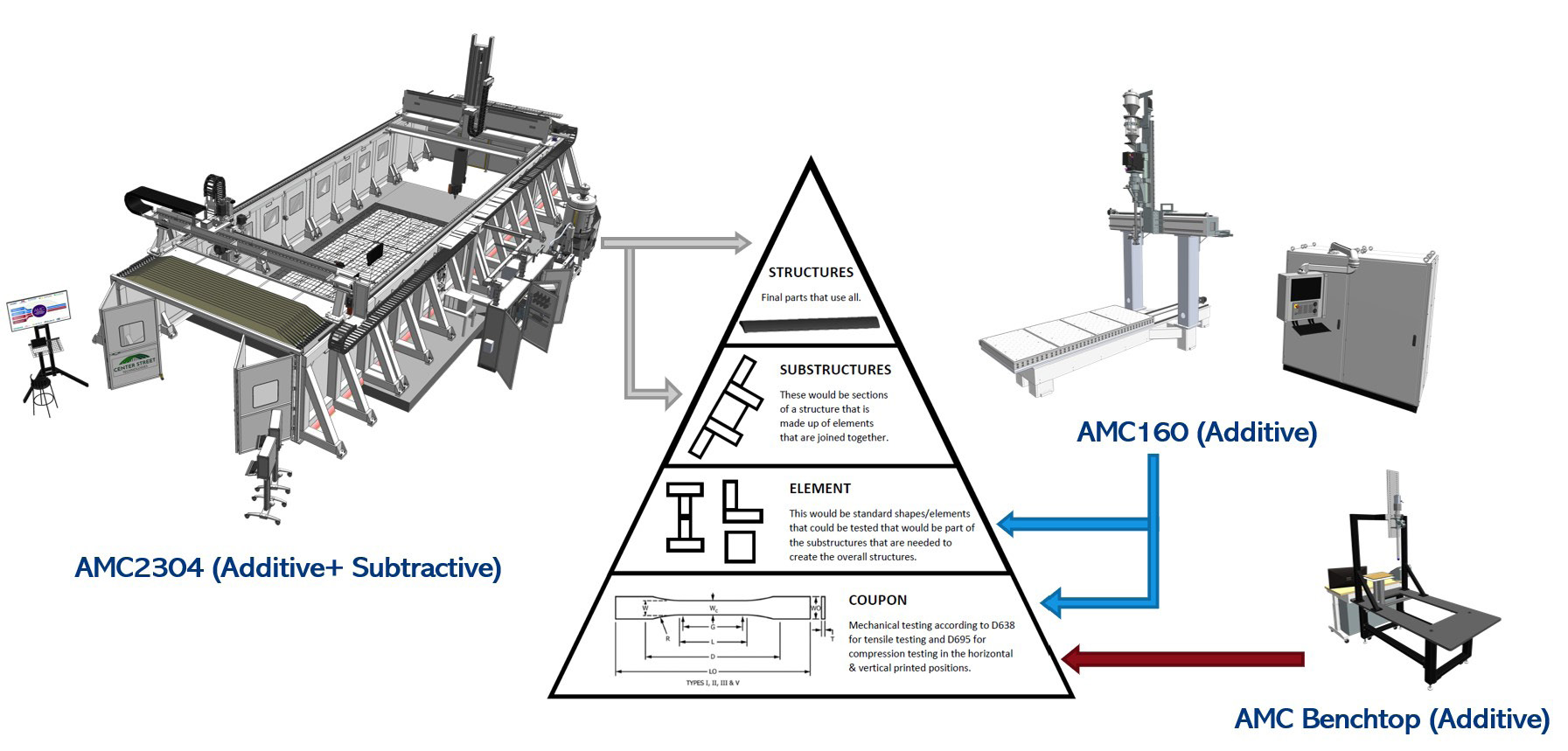

AMC development and characterization assets (R) and full-scale dual gantry hybrid manufacturing system (L)

Problem

Over the last 70 years our nation has atrophied in its capability to rapidly develop large prototypes and useful reproductions, particularly in the realm of Defense. To maintain our operational advantage, there is a need to develop and maintain an affordable and reliable industrial base for massive-scale prototypes that will be responsive to warfighter needs as well as reduce cost, improve component and system quality, and enhance industrial capability.

Objective

Develop an agile advanced manufacturing confluence (AMC) platform to manufacture simple and complex geometry large-scale polymer components in a variety of materials. The platform will utilize the complete physical volume of the platform or simultaneously build a mix of components. To accomplish this, the team is building on the developments in the Phase 1 project to achieve the following:

- Producing large-scale polymer and polymer composite structures, tools, and prototypes

- Integrating digital thread throughout the process chain

- Establishing processing capabilities for materials of value to government and industry customers

- Growing and diversifying the U.S. Defense Industrial Base

Technical Approach

Center Street Technologies (CST) is building off the Phase I effort to continue to integrate capabilities on its physical and digital AMC platform that serves as a critical test bed for material evaluation and component selection. Investment continues on four pillars of Industrial Controls & Automation, Materials Science, Application Design & Engineering, and Advanced Modeling and Simulation. The overall approach is to identify, configure, demonstrate, and produce through the following tasks under this phase:

- Data management and security: updating data elements and parameters and integrating in-situ sensors and security protocols for wireless data transfer.

- Materials characterization and optimization: evaluating materials for engineering and high-performance applications to meet high strength, durability, dimensional stability, and mechanical integrity at high temperatures.

- Materials development: determining if thermosets can be processed, and if fiber reinforcement can enhance stiffness and breaking strength.

- Process development: continuing process development to ensure a high probability of first-build success.

- Partnerships: continuing existing and forming new partnerships to advance in areas such as embedded systems, materials testing, 5-axis machining, supercomputing applications, and advanced part handling.

Project Participants

Project Principal

Public Participants

- U.S. Department of Defense