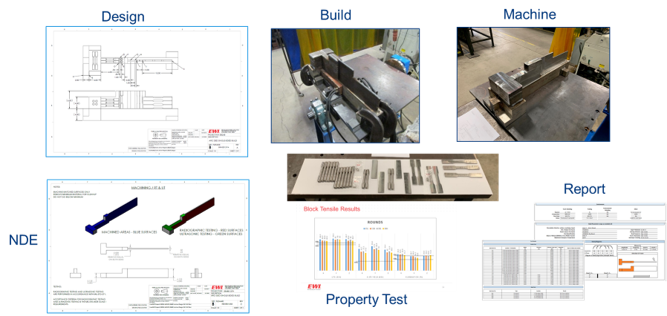

Develop, demonstrate, and transition prescriptive prototype qualification and fabrication requirements via the approach of design, build, machine, nondestructive evaluation, property test, and reporting.

Problem

Additive manufacturing (AM) processes are high-impact manufacturing processes for Naval Sea Systems Command (NAVSEA ) parts and components, offering the capability to produce parts at low production volumes. To implement AM methods, qualification and fabrication requirements must be developed. Some have been established through previous project efforts, but NAVSEA identified additional supporting processes and technology topics that were addressed within this project to provide updates to the NAVSEA Technical Publications for powder bed fusion (PBF) and direct energy deposition (DED).

Objective

The overall goal of the project’s three-year effort was to develop additional procedure qualification schemes/components, support process requirements, and pertinent fabrication requirements to update NAVSEA Technical Publications for both metal DED and metal PBF including electron beam powder bed fusion (EB-PBF), electron beam wire fed DED (EB-DED), and laser powder fed DED (PL-DED) thus accelerating the implementation of these related technologies. The project also developed both prescriptive requirements and best practices to improve metal AM process qualification affordability, avoiding “special” procedure qualifications that increase cost and schedule.

Technical Approach

EWI, the NAVSEA Technical Warrant Holder (TWH) for AM, and the Naval Surface Warfare Center Carderock Division (NSWCCD) identified a list of supporting processes and technology topics that need to be addressed to complete the development of these NAVSEA Technical Publications.

The initial work established the procedure qualification schemes for arc DED processes using integrated and non-integrated build platforms and for both single-sided and double-sided standard quality build (SQB) designs, nondestructive evaluation (NDE) procedure map, property matrix, and qualification records for each application and process combination. Because these AM processes cover a range of feature size capabilities defined by minimum bead width, the SQBs were designed for full scale (≥ 5mm) and subscale features (2-5mm). The previous efforts identified the need to develop mini SQBs for processes with features approximately < 2mm bead width.

Phase I focused on developing NDE requirements for the SQBs, developing mini SQBs and the test specimen designs to complete EB-PBF build layout, test array, and demonstration builds along with EB-DED and PL-DED procedure qualification scheme and demonstration builds. Phase II advanced this into curved integrated builds using pulsed gas metal arc (GMA-P) DED, developed fabrication requirements for DED support processes, identified how materials and build process parameters affect acoustic properties, and recommended in-situ liquid nitrogen cryogenic cooling (ILNCC) procedure requirements for inter-pass temperature control and qualification. Phase III focused on the validation of NDE flaw detection capabilities.

The results of all tasks support additional input into the development of the PBF and DED Technical Publications that continue to be completed throughout the three-year/three-phase project.

Accomplishments

This three-year project accelerated requirements implementation for wire-fed DED, powder-fed DED, and EB-PBF metal AM processes. Qualification schemes (build design, NDE maps, specimen sectioning drawings, and application qualification reports) were developed for a comprehensive range of material-process metal AM applications. This included qualification build designs for three levels of scale (mini-, sub-, and full-scale) features, flat and curved build platforms, integrated and non-integrated build platforms, and single- and double-sided build applications. These schemes were demonstrated on wire gas metal arc, wire gas tungsten arc, wire laser, powder laser, wire electron beam DED; and electron beam PBF processes. To support the NDE of qualification builds, a calibration block matrix representative of different DED materials and features was built and examined. Additional 308L stainless steel acoustic blocks were added to evaluate the complicated directional behavior of ultrasound observed in stainless steel DED deposits. Inspection approaches for flaws representative of natural flaws from DED processes were demonstrated using ultrasonic methods and radiography on three builds of 308L stainless steel. In addition, requirements for in-situ liquid nitrogen cryogenic interpass cooling, infrared camera interpass temperature control calibrations, and arc deposition start/stop procedures were evaluated for Technical Publication requirements development.

Project Participants

Project Principal

Other Project Participants

- NAVSEA/Carderock

Public Participants

- U.S. Department of Defense