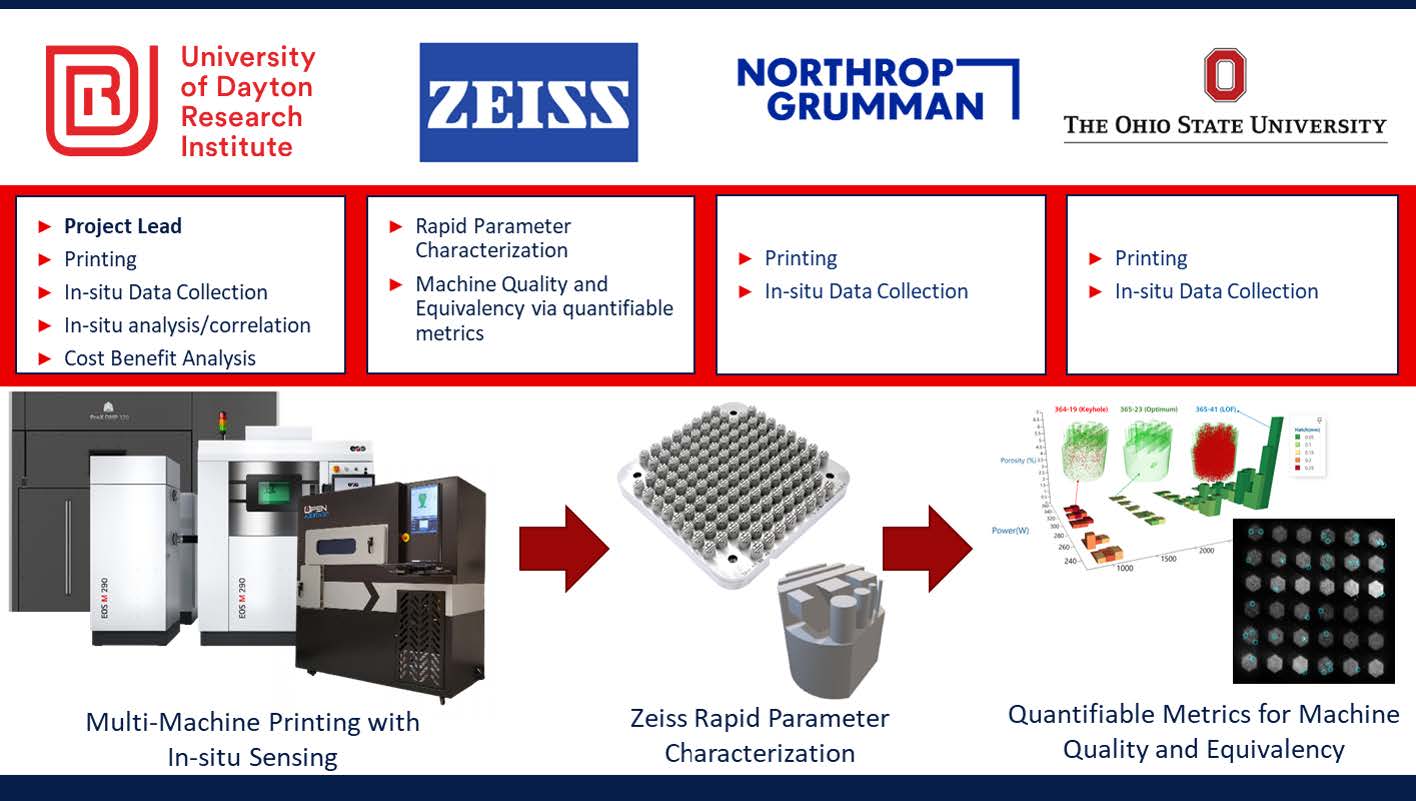

Zeiss AM Parameter specimens are printed across three machine types. Specimens are characterized via X-ray CT to generate quantifiable metrics for build quality and machine equivalency. Metrics are correlated to in-situ sensor data.

Problem

Machine operators and quality engineers lack a consistent, universal method for quantifiably benchmarking system performance over time versus other metal additive manufacturing (AM) machines, aside from large specimen testing campaigns. There is a significant need for streamlined postpart characterization and in-situ data monitoring processes that can rapidly inform machine variation and process equivalency across the industry.

Objective

The objective of this project is to develop streamlined post-part characterization and in-situ data monitoring processes that can rapidly inform machine variation and process equivalency across the industry including:

- Establish Nondestructive Evaluation (NDE) metrics for machine-to-machine equivalency

- Establish NDE metrics for repeatable measurement of machine quality

- Benchmark sensor data consistency across multiple machine types, enabling quantification of machine quality and machine-to-machine equivalency

- Track sensor data metrics for direct correlation with NDE metrics

Technical Approach

The University of Dayton Research Institute (UDRI), Northrop Grumman (NG), and The Ohio State University (OSU) will print the Zeiss Rapid AM Parameter Matrix using Ti6Al4V. The matrix will be printed across three machines including: an EOS M290 (UDRI), a ProX DMP 320 (NG), and an Open Additive PANDA (OSU). In addition, in-situ infrared (IR) tomography sensor data will be collected utilizing the same sensor package across all prints. ZEISS will perform Rapid AM Parameter Characterization of all printed parts via X-ray computed tomography (CT). Zeiss will quantify machine performance via measurement of porosity and distortion from computer-aided design (CAD) . Sensor data will be correlated to NDE machine quality results via measurement of thermal statistics, data anomalies, and correlation to NDE. A Cost/Benefit Analysis of this streamlined approach will be performed based upon the strength of conclusions drawn from comparison/ equivalency analysis.

Project Participants

Project Principal

Other Project Participants

- Carl Zeiss Industrial Metrology, LLC

- Northrop Grumman Corporation (NG)

- The Ohio State University

Public Participants

- U.S. Department of Defense