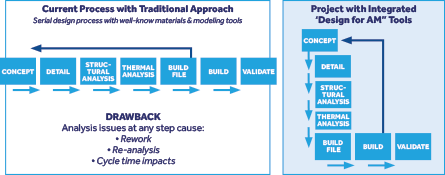

Move from a serial process, consisting of islands of sub-optimization and manual design manipulation, to a seamless integrated rule-based environment capable of achieving advanced design features.

Multidisciplinary Design Analysis for Seamless Additive Manufacturing Design, Analysis, Build, and Redesign Workflows

Problem

Design for Additive Manufacturing (DFAM) allows for improvements, such as lightweighting structures by more than 50% and enhancing thermal performance by more than 20%, but it is currently a long and manual process of optimization. CAD/CAM/CAE software currently forces serial processing of the design through islands of sub-optimization and manual design manipulation; failure at any of these serial steps usually results in starting the entire process over.

Objective

The objective of this project was to address the development of a methodology to create Design For Manufacturability (DFM) criteria and rules for advanced design features. Additionally, the project also sought to improve software techniques for design performance optimization, which subsequently made step-change improvements in the cycle time required to perform additive manufacturing (AM) CAD/CAM/CAE analyses and design optimization, and allowed for the exploitation of AM on multiphysics design enhancement. Initial machine material datasets were also created along with process workflows and characterization methodologies.

Technical Approach

The project research of this collaboration team made up of DoD and commercial primes, including four of the major software suppliers, in conjunction with two research institutions will benefit the entire AM industry. The team developed an approach in three phases:

- Phase 1 – Evaluate currently available design workflows and CAD/CAM/CAE analyses and design optimization software.

- Phase 2 – Develop models.

- Develop demonstration models that enable characterization of design, materials, and features. (GE and Raytheon)

- Develop a coupled thermal-structural topology optimization approach constrained by characterized parameters. (University of Wisconsin)

- Develop demonstration models for the optimization of electro-mechanical performance parameters. (UMass Lowell/RURI)

- Phase 3 – Build, test, and develop design rules for software insertion and modified workflows to allow a reduced design build cycle time, enable simultaneous trades to be performed, and create a methodology for additional processes and materials.

Accomplishments

The team successfully mapped out Raytheon and GE’s design process flows, which are required to execute design and analysis for both lightweight and down-selected enhanced features for multi-disciplinary engineered structure designs (e.g., repeated sub-sections, systematic geometric transitions, and boundary conformal geometry) that are important for numerous applications.

Raytheon and GE started by installing all of the CAD/CAM/CAE software and received training from the suppliers. The team also:

- Performed a detailed assessment and gap analysis of the participating software suppliers to assess capabilities relative to structural optimization.

- Made recommendations for an integration strategy and software improvements where gaps are identified.

- Created a design model of the demonstration designs with initial lightweighting and enhanced multi-disciplinary engineered structure design features, such as repeated sub-sections, systematic geometric transitions, and boundary conformal geometry, which were tested through the design, analysis, build, and validation processes.

- Defined a set of design rules for lightweight and the other down-selected enabling enhanced features.

- Developed a coupled thermal-structural topology optimization constrained by parameters to improve additive manufacturability based on the demonstration models focused on:

- Minimum feature thickness: the optimized structures should not contain feature smaller than a pre-specified dimension.

- Minimum wall angle: the optimized structures meet thermal-structural requirements while reducing unbuildable overhangs and shallow wall angles.

- Conducted tests and results analysis for electro-mechanical integration demonstrations.

The CAD/CAE software tools were made available for evaluation and training to both the America Makes Innovation Factory, as well as the satellite location at the W.M. Keck Center at the University of Texas El Paso.

Milestone Video

Project Participants

Project Principal

Other Project Participants

- GE Global Research Center

- Autodesk, Inc.

- Altair

- ANSYS, Inc.

- University of Wisconsin–Madison

- University of Massachusetts Lowell

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy