Key focus areas for virtual verification and validation of parts across different manufacturing platforms.

Problem

The Army has developed the process for additively manufacturing and post-processing ramjet projectile inlet nozzles and nickel rotating bands. To scale production, a method is needed to ensure the as-built quality of these components when produced on different additive manufacturing (AM) build platforms. Current approaches for process qualification, also known as system equivalence, require many coupons and parts to be built and tested. This often costs upwards of $1M and can take up to six months.

Objective

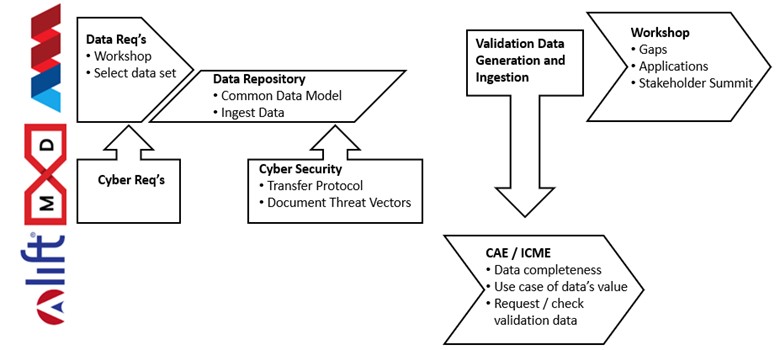

The goal of this multi-year, long-term project was to qualify structural parts for use directly from the manufacturing process without a non-destructive evaluation or lot acceptance testing step. This effort focused on understanding the primary factors influencing product quality and how they can be captured in the digital build log during manufacturing. The team utilized existing data from America Makes, LIFT, and MxD, and determined minimum data needs to ensure interoperability of the framework across various platforms.

Technical Approach

This project was a direct contract with the LIFT Institute (American Lightweight Materials Manufacturing Innovation Institute {ALMMII} – aka LIFT) to provide America Makes support in a multi-institute effort for ONR. Additional participants included NCDMM (America Makes), MxD, and EWI. Several methods were used to drive activities throughout the project. The first step was improving upon the advanced manufacturing qualification and certification approaches developed for AM by the Army and extending to other forms of advanced manufacturing needed to produce a system. Another aspect was to review existing data sets and define the minimum data requirements that would enable verification and/or validation of a data set. The team also conducted roadmap modeling and predictive analytics to communicate AM design, material, process, and part performance data across platforms. With these approaches in mind, the team established preliminary training for the utilization of data sets and established a secure data transfer portal.

Accomplishments

This project achieved a proof of concept that equipment health monitoring can be used to establish effective quality envelopes. Although the proof of concept targeted a conservative use case, which included a production-relevant variation in gas flow and laser-quality, conservative coupon geometries (15 mm diameter cylinders), a well-controlled material (IN718 built on an EOS M290 with EOS provided process parameters), and the use of HIP to eliminate defects, the results showed that the use of an equipment health-based quality envelope could improve Low Cycle Fatigue (LCF).

Several key technical elements were leveraged to accomplish goals:

- Planned, executed, and reported on a three-day workshop titled “Data Enabled AM Process Qualification Workshop”

- Identified primary data elements that were important to accelerating AM process qualification

- Directly measured subsystem performance across the build envelope using the EWI gas flow measurement rig and laser pin hole measurement system

- Repeatably varied equipment health performance on a single system to represent a production-relevant range of AM equipment variability

- The use of Bayesian optimization and FEA simulation to design coupons with thermal history variation

- A design of experiments that allowed a wide range of effects to be studied in an efficient way

- The use of descriptive, diagnostic, predictive, and prescriptive analytics to quantify the effects of variability on material properties

Project Participants

Project Principal

Other Project Participants

- NCDMM/America Makes

- Edison Welding Institute (EWI)

- Digital Manufacturing and Cybersecurity Institute (MxD)

Public Participants

- U.S. Department of Defense