A variety of challenges related to measurement sciences limits the adoption of additive manufacturing for many industries that require qualified parts.

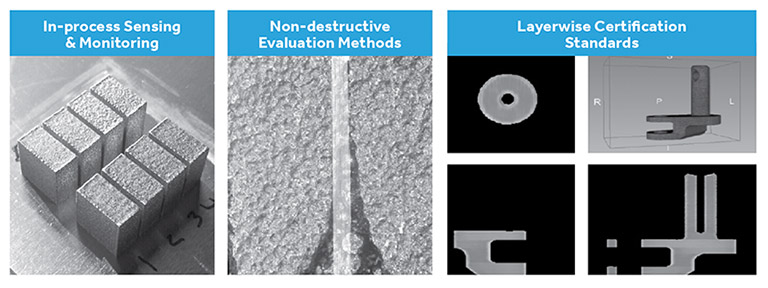

This project involved a three-part research plan to ensure that quality additive manufacturing (AM) parts are produced, and certified, for use in products manufactured by a variety of U.S. industries and their supply chains. This plan included 1.) in-situ process monitoring, 2.) non-destructive evaluation, and 3.) layerwise quality certification for AM.

Problem

Additive manufacturing (AM) presents a variety of measurement science challenges which limit the broad application of AM for performance-critical parts. Current commercial laser powder bed fusion (LPBF) machines operate in an “open loop” manner, with little or no real-time monitoring of the process to ensure quality requirements are consistently achieved.

Objective

The objective of this project was to address metallic material systems and manufacturing processes in three high priority thrust areas to:

- Develop, integrate, and validate a robust, informative in-situ process monitoring capability to ensure part quality

- Develop and validate a non-destructive evaluation (NDE) standard to establish quality certification methods well suited to AM

- Create a 3D Quality Certificate (3DQC) for each manufactured part using run-time process monitoring data indexed to part geometry

These thrust areas would help ensure that quality parts are produced and certified for use in end products across multiple manufacturing industries.

Technical Approach

The measurement science challenges were divided into three focused research tracks:

In-Process Sensing and Monitoring

Led by EWI, this research team evaluated, developed, and integrated a variety of thermal, visual, and acoustic sensing techniques on an LPBF platform. Evaluation techniques included variable part quality conditions and industrial printing systems.

NDE Methods

The team led by Concurrent Technologies Corporation (CTC) focused on maturing flaw seeding techniques within test specimens and establishing accurate and reliable NDE size limitations for detecting the seeded flaws.

Layerwise Certification Standards for AM

The research team led by the University of Louisville used thermal monitoring of each layer during a part build and compared it to a layer-by-layer quality certification template created from the STL file for the component. This produced a Layerwise Quality Certification standard that can be used for the AM industry.

Project Participants

Project Principal

Other Project Participants

- Concurrent Technologies Corporation

- University of Louisville

Public Participants

- U.S. Department of Commerce

- National Institute of Standards and TechnologyNational Institute of Standards and Technology