Project Title: Open Analytics Platform for Multi-Sensor In-Situ Monitoring

America Makes Project Number: 5001.001.001.004

Project Title: Open Analytics Platform for Multi-Sensor In-Situ Monitoring

America Makes Project Number: 5001.001.001.004

America Makes hosts project calls to increase member engagement while benefiting the broader AM supply chain through execution of strategic research initiatives, sharing results and lessons learned, encouraging communication and participation in Institute working groups, advisory groups, steering committees, and America Makes hosted forums.

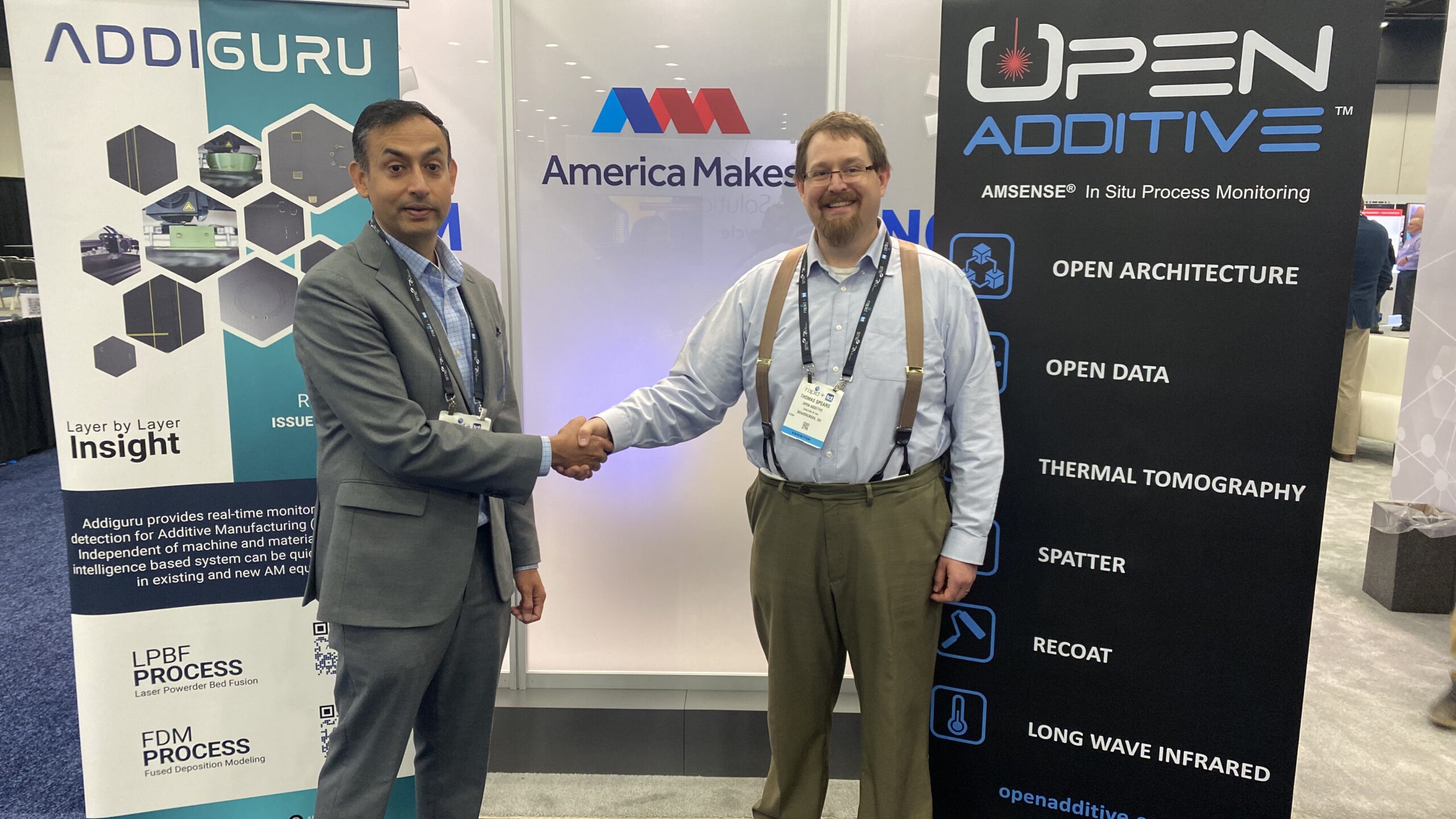

During the 2022 RAPID + tct conference in Detroit, MI, the America Makes team had the opportunity to hear firsthand how members work collaboratively during project calls to make this happen.

Together, Dr. Thomas Spears, Associate Director of Agile Additive Manufacturing Technologies at Open Additive, and Shuchi “SK” Khurana, Founder of Addiguru, spoke with team members present at the event and explained how their partnership has grown over the years – far exceeding their initial expectations.

The relationship began in 2020 when the companies worked together during an open project call on what would eventually be titled Open Analytics Platform for Multi-Sensor In-Situ Monitoring (5001.001.001.004). Open Additive served as the project principal, alongside project partners AddiGuru and Wright State University. “The project’s overall goal was to evaluate sensor fusion techniques for detecting reliability issues in LPBF (laser powder bed fusion) production,” Spears explained. “One particular objective was to demonstrate the deployment of Addiguru’s recoat issue detection analytic within our AMSENSE software framework.”

Spears stated that from its onset, the working relationship was complementary. Although the project was challenging, the team mindset remained focused and highly collaborative. “We worked closely to develop the software interface between AMSENSE® and the Addiguru software,” he said. “During the project, we collected data on our PANDA™ LPBF machine and worked with Addiguru to retrain their model with real-world data. That process involved designing specific builds to produce data for retraining and subsequent testing.”

Four months into the project, the companies formalized their collaboration with a Memorandum of Understanding (MOU) that set the foundation to continue their work towards more open and affordable industrial process monitoring and control for metal AM.

“Having Addiguru as a partner allowed us to bridge a gap in our analytics portfolio and increase the impact of our AMSENSE offering. The work also aided in refining the challenges of LPBF monitoring technologies to ensure that we are properly focused on solving the correct problems for industry,” Spears said. “Additionally, both companies were eager to create a product – and not just a report, which directed our project activities toward productive outcomes.”

According to Khurana, Addiguru’s long-term goal is to provide solutions directly integrated with the machines and software already being utilized. “Embedded Addiguru software will make it easier for the user to implement our solution in their manufacturing process and save both time and money. Our partnership with Open Additive is the first execution of an external integration that we implemented,” Khurana said. He is confident that additional integrations are forthcoming.

They agreed they were able to create something better than originally envisioned because of a shared trust that developed early in the process.

For both companies, answering this project call was their introduction to all that America Makes membership offers, including networking, access to industry experts, project calls, funding, and more. Spears noted that his company continued its trajectory by submitting, winning, and executing a follow-up program with other America Makes members to further refine technology solutions for industry’s most challenging problems. “Working with America Makes and its membership has provided Open Additive with broad exposure to industry and industry challenges, and in some cases enabled us to mature and transition technologies that otherwise would not have been possible. We certainly look forward to future projects and partnerships with America Makes and its members.”