The efforts of this project will provide a framework for attaining allowables for future alloys utilizing the L-DED process.

Problem

One of the most significant gaps to the approval of additively manufactured (AM) parts is a lack of widely accepted and available design data for use by engineers and designers. Generating the requisite data and models requires a significant investment of resources and time to produce statistically significant data, which involves creating test coupons under a controlled process, and performing testing and analysis of the resulting data. While there are some existing proprietary AM design databases, there is currently a very limited amount of publicly available industry or government-accepted standard design data for AM processes and materials. This data is needed across the government and industry to accelerate the broader adoption of AM.

Objective

The purpose of the project is to develop a systematic approach to the generation of statistically based bulk material properties for Ti-6Al-4V via laser powder feed directed energy deposition (L-DED), which helps address the gap within the defense and commercial industry in design allowables for the L-DED process. Another goal is to provide a framework for attaining allowables for future alloys utilizing the L-DED process. Boeing is eager to further establish the foundation of AM and the available design data for AM materials/ processes to accelerate the adoption of AM as a repeatable, robust method to fabricate flight-worthy parts.

Technical Approach

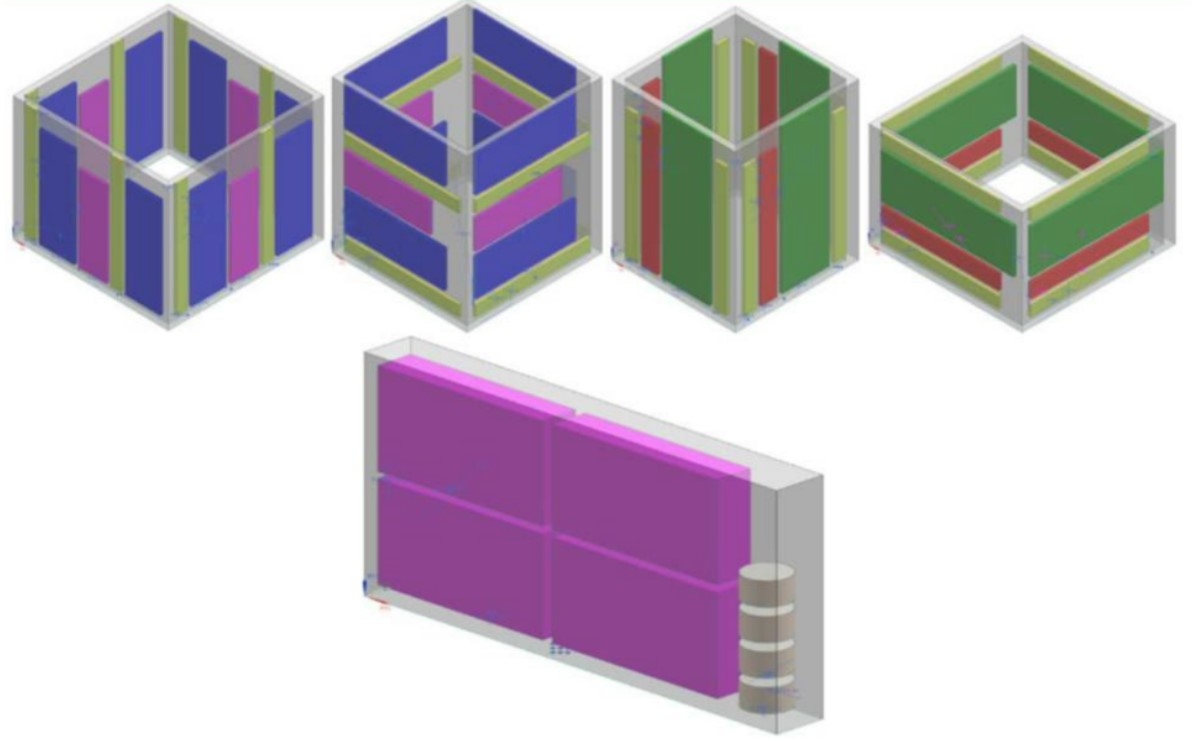

Leveraging the capabilities of each strategic partner, the first task consists of a comprehensive study of the L-DED process and the characterization of all necessary data to support the generation of bulk metallic material property data that can be reliably replicated. Utilizing the lessons learned from the first task, RPMI and Boeing are constructing a process control document (PCD) that includes the machine operation procedures and KPV tolerances. The PCD is being developed in conformance with AMS7010A to enhance the transition into publicly accessible availability. Boeing and the team will develop and demonstrate a workflow that addresses Metallic Materials Properties Development and Standardization (MMPDS) allowables generation guidelines to deliver statistically relevant material allowables for L-DED Ti-6Al-4V tensile, compression, shear, bearing, and fatigue properties. The test matrix includes consideration for the relevance and design of test specimen blank preform extraction plans and includes multiple coupon orientations. Production of material will occur using multiple (5) AM machines with feedstock from two powder suppliers.

Project Participants

Project Principal

Other Project Participants

- National Institute for Aviation Research (NIAR)

- The Ohio State University

- NCDMM/America Makes

- The University of Texas at El Paso (UTEP)

- Auburn University

- Edison Welding Institute (EWI)

- RPM Innovations (RPMI)

- American Society for Testing and Materials (ASTM)

Public Participants

- U.S. Department of Defense