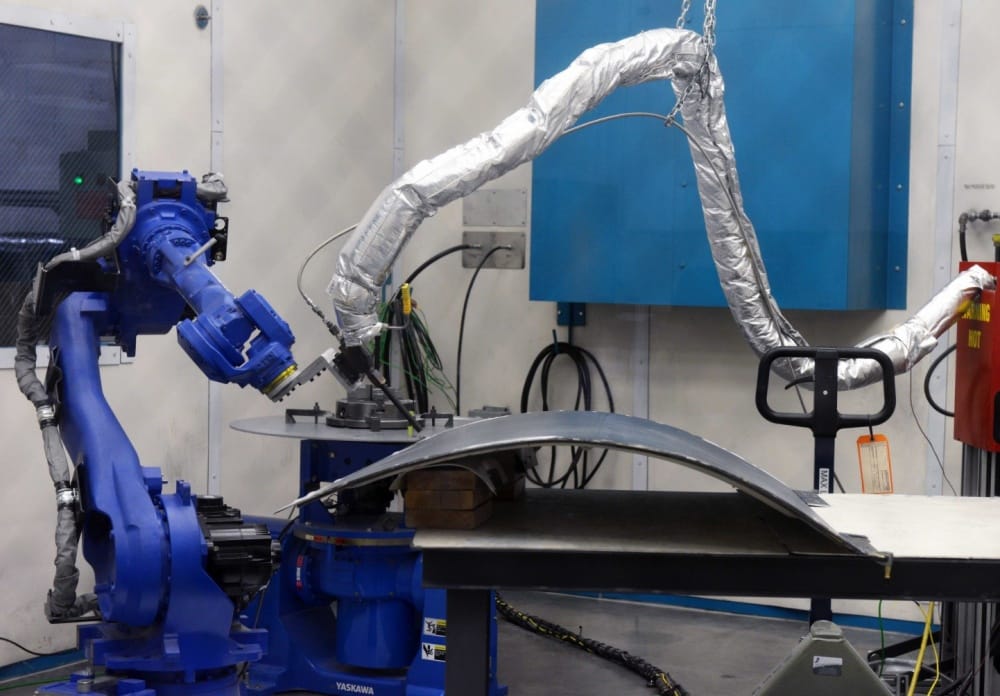

Cold spray operations with a robotic arm.

Problem

Obtaining approval for cold spray operations is a difficult effort, as there is currently no established approval process in place. Without a clear approval process, best practices, or other guidance, the safe and proper implementation of cold spray technology will be significantly delayed or may not happen at all. The absence of clear direction will result in the unsafe use of cold spray technology and create unnecessary risks to the environment, safety, and occupational health (ESOH). Additionally, it will result in missed opportunities to capitalize on the cost, readiness, and performance benefits that cold spray operations offer.

Objective

The objective of this project was to provide the Office of the Secretary of Defense (OSD), all individual Services (Air Force, Army, Navy), and other United States Government (USG) locations with a method for facilities to gain authorization for the implementation of cold spray operations. Authorization included facility ESOH staff, onsite and local fire departments, environmental management agencies, and other authorities associated with approving industrial processes at Department of Defense (DoD) facilities.

Technical Approach

The project approach included discussions with operations personnel, engineering authorities, and safety and facilities management personnel, as well as conducting on-site visits. The intent of the effort was to assess the safety, facility, and environmental factors associated with cold spray manufacturing operations. Examples of these factors included fire hazards, hazardous materials, facility structural requirements, utilities, and environmental safety issues, as well as measures taken to mitigate them. Assessments for the implementation of cold spray were conducted at multiple locations and prioritized through collaboration with the Government Technical Project Manager. The implementation criteria included consideration of various federal, state, and local regulations. The team documented lessons learned to initiate the development of best practices for USG locations to streamline the approval process for cold spray implementation.

Accomplishments

The NCDMM and Telgian team conducted facility and equipment analyses as well as onsite visits and hazard assessments to identify compliance with local, state, and federal regulations and risks associated with implementing cold spray technology into operations at:

- Hill Air Force Base (AFB);

- Jacksonville Naval Air Station – Fleet Readiness Center Southeast (FRCSE);

- Naval Base Kitsap; and

- Robins AFB

A draft Dust Hazard Analysis (DHA) report was developed for each location and was discussed with site staff for feedback. Once site staff agreed with the report, it was stamped by a Professional Engineer and delivered as final.

The DHA reports developed, and activities executed under this project provide confirmation for cold spray implementation or a path for cold spray implementation, including risk mitigation, for the four DoD locations listed above, which exceeds project Key Performance Parameter (KPP) objectives by 25%.

Identified best practices include:

- Conducting an analysis of the equipment, facility, dusts, and hazards;

- Identifying a specific operating location for the use of cold spray technology;

- Having specifications and operating requirements for the use of cold spray and supporting operational equipment, as well as the type and quantity of metal powders expected to be sprayed and the associated material safety data sheets;

- Explaining the intent to implement cold spray to site staff including but not limited to operations, industrial hygiene, safety, environmental, fire brigade, and others to gather input and requirements; and

- Communicating throughout the implementation process with site staff listed in the prior bullet and possibly offsite organizations, i.e., Army Corps of Engineer districts, to ensure that requirements are met, and implementation delays are minimized.

Project Participants

Project Principal

Other Project Participants

- Telgian Engineering & Consulting

Public Participants

- U.S. Department of Defense