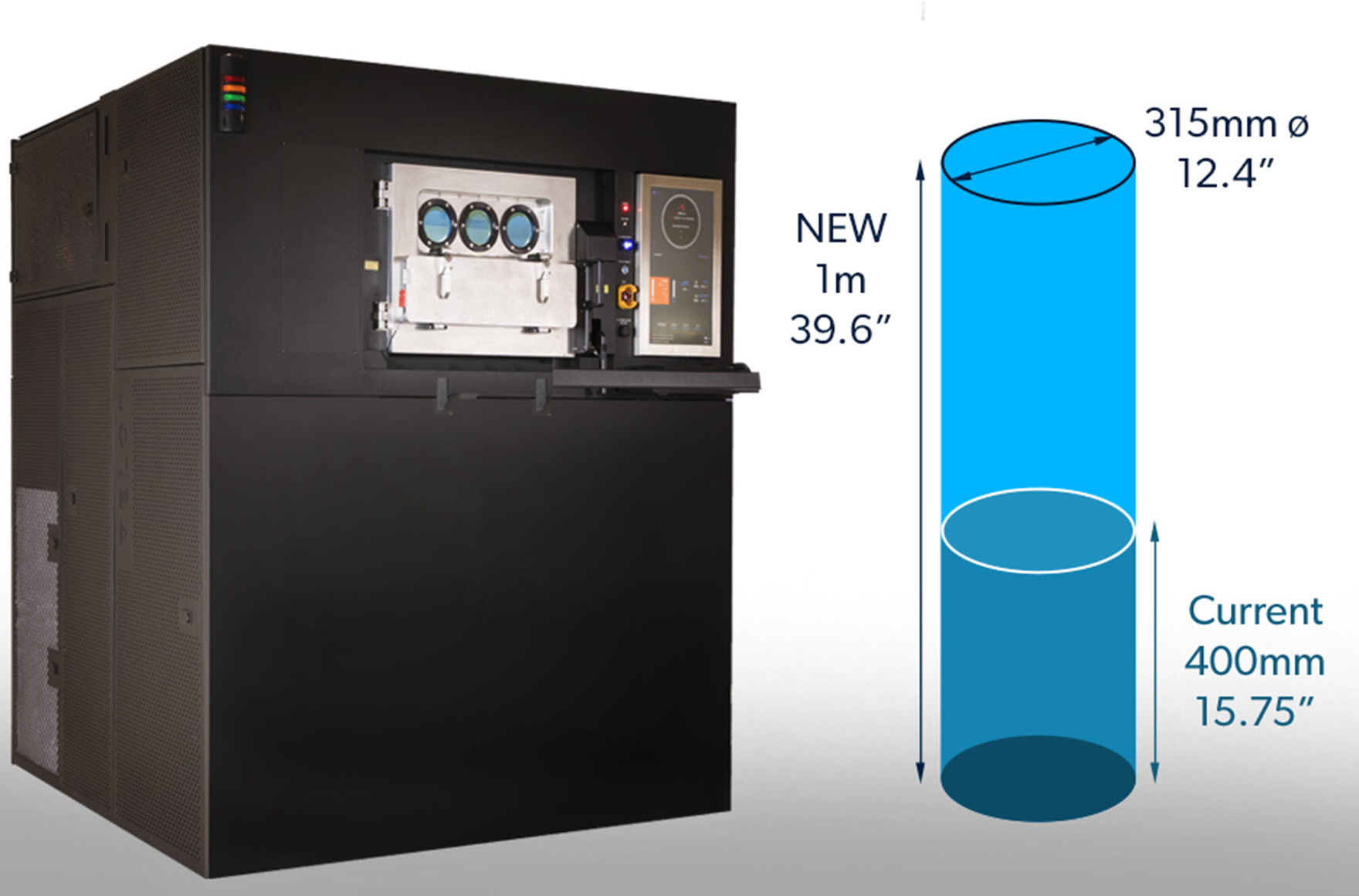

Velo 3D offers design flexibility, thermal stability, and geometric stability of 1-meter tall system.

Problem

Complex internal flow paths have been a strong driver in the growth of metal additive manufacturing (AM), and specifically laser powder bed fusion (LPBF). As the flow paths become more complex and the parts grow in size, however, there are current technology limitations that hinder this growth. Specific shortcomings in the current implementation of LPBF include the inability to print low-angle overhangs without support; the dimensional accuracy and consistency of given geometries, especially in the case of thin walls and tall (i.e. long) builds; and the height of a part that can be built in a single print.

Objective

The objective of this project was to address the shortcomings of LPBF in printing low-angle overhangs without support and manufacturing taller (up to 1 meter) AM parts in a thin-walled cylinder, leveraging both additive and traditional (welding) manufacturing of Inconel alloy 625 (IN625). Specifically, this project developed and demonstrated low angle (< 45 degrees from the build plane) LPBF print capabilities in IN625; demonstrated the print of a tall (longer than 20 inches) thin-walled cylinder and developed and demonstrated a draft weld procedure specification for IN625 with associated initial mechanical evaluation.

Technical Approach

Aerojet Rocketdyne led the project team which included Velo3D. Aerojet Rocketdyne designed geometry demonstration samples for fabrication and testing. The team fabricated deliverable samples of IN625 components on a Velo3D Sapphire 1MZ machine capable of printing 1-meter tall parts and post-process accordingly. They verified the consistency of printed material with a pressure test of geometry demonstration samples. Finally, Aerojet Rocketdyne performed welding trials and developed a draft welding specification.

The focus of the project was on three main technical areas:

- Developed and demonstrated low-angle printing down to zero degrees without the use of supports;

- Demonstrated printing tall, thin-walled cylinders longer than 20 inches; and

- Developed and demonstrated a draft weld procedure for IN625 along with the mechanical evaluation of the weld.

Accomplishments

This project fabricated microstructure samples with all of the multi-parameters surveying X, Y, and Z envelopes in both the as-built and thermally processed conditions. A manifold representative of a critical area on an archetype part was printed and the microstructure reviewed to study multi-parameters in a component. Mechanical testing from the entire build envelope included tensile, low-cycle fatigue (LCF) and high-cycle fatigue (HCF) both smooth and as-built. Finally, a component that represents the limit of the Velo3D Sapphire 1MZ machine, excluding sensitive geometries, was designed, fabricated, post-processed, proof, leak, and burst tested. Joining of these components was necessary so welding trials were developed. Finally, feature builds were built, analyzed, and incorporated into a design guide written by Velo3D for alloy IN625.

Some highlights from the microstructure and mechanical testing included:

- Velo3D scan types were recognizable in as-built optical metallography, referred to as bulk core, skin, upskin, and low angle parameter.

- Low angle parameter included an intricate sequence of sub-elements.

- Velo3D parameters enabled fabrication of low-angle surfaces.

- As-built microstructures appeared identical irrespective of height above the build plate.

- From the available data, tensile, LCF, and as-printed surface (APS) HCF properties were in family with data seen for other SLM IN625 characterization efforts.

- For all data sets, laser, build sample location and orientation did not appear to affect data.

- From the full height tensile data, tensile properties showed little variation and remained consistent throughout the build volume.

Project Participants

Project Principal

Other Project Participants

- Velo3D

Public Participants

- U.S. Department of Defense