Parameter Developmental Builds

Problem

Powder bed fusion (PBF) and material extrusion enables the manufacture of flight- ready parts quickly and cost -effectively. Existing media for these processes, such as polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), nylon, and glycolized polyester (PETS), have melt temperatures between 170-280°C. Feedstock materials, formulations, a cross-linking process to structurally stabilize the parts after being additively manufactured, and a firing process are needed to enable additive manufacturing of aircraft structural shapes capable of temperatures at or above 2000° C.

Objective

The objective of this program is to develop PBF and material extrusion material formulations that yield high temperature microstructures, greater than 2000°C, for aircraft structural shapes. Specifically, the effort seeks to examine and validate heat treating processes and the resultant mechanical properties of carbon-carbon (C-C) and carbon silicon-carbide (CSiC).

Technical Approach

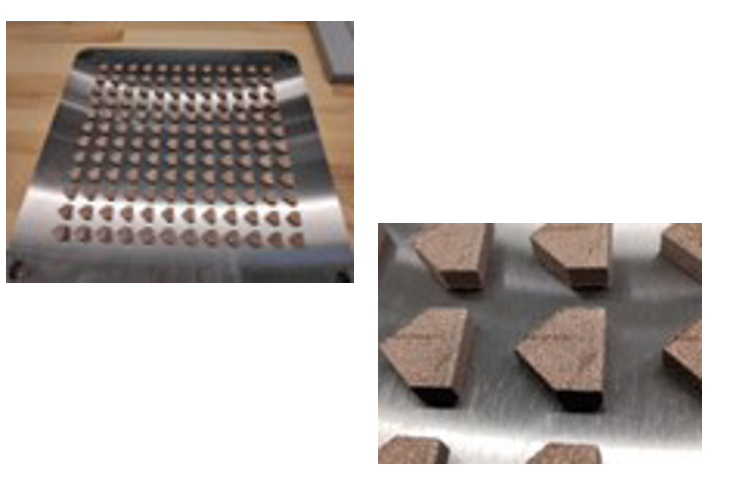

The technical approach is to utilize petroleum pitch and silicone resins along with carbon/graphite and silica fillers, organic solvents, catalysts and other modifiers, and fugitive materials that burn away when fired and leave small voids in the material to decrease thermal conductivity, increase insulation, and reduce density to produce thermo-set compounds. These compounds are then formed using additive manufacturing and subsequently thermally processed to result in structures suitable for high temperature applications. Primary activities include characterizing raw materials for physical and thermal behavior to create a database for formulations; compounding trials and evaluations in a torque rheometer followed by grinding and solvent with high shear mixing, drying, and grinding; materials characterization; pill formation and heat treatment trials; and formulating, processing and evaluating mechanical properties of the C-C and CSiC materials to manufacture structures using PBF and material extrusion printing.

Project Participants

Project Principal

Other Project Participants

- NCDMM/America Makes

- Keraskjold Materials Development LLC

Public Participants

- U.S. Department of Defense