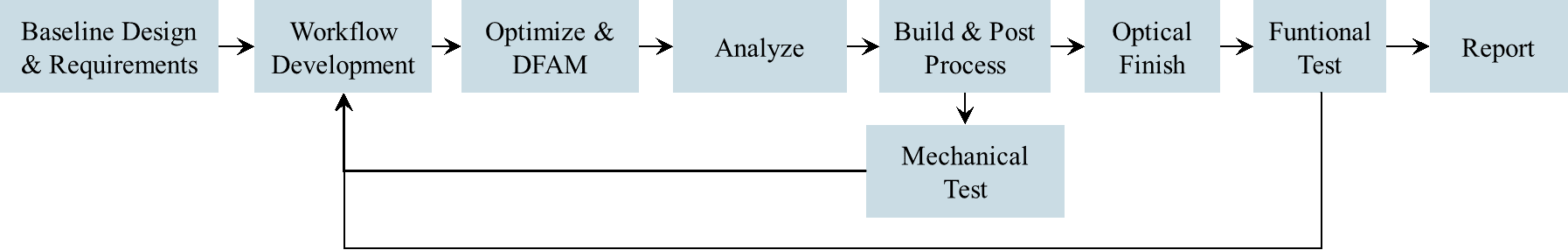

TORO process flowchart

Problem

Optical components for aerospace and defense are among the highest precision components produced worldwide. Extreme micro-stability, stiffness, weight, thermal, and geometric requirements demand the most advanced materials and designs. Despite advancements in topology optimization (TO) and additively manufactured (AM) production of optical components, there are still optical applications that rely on traditional design and manufacturing methods using toxic and expensive materials like beryllium. The use of these toxic materials, which are expensive and pose significant health risks, is often justified when there are no other design or material choices available. These constraints threaten the mission of ‘delivering performance at the speed of relevance’ for emerging national security threats.

Objective

In moving from a baseline design of a traditionally manufactured optical mirror/mount assembly to an exotic AM design enabled by advances in nTopology (nTop) Platform, the TORO team established the following objectives: 50% reduction in build cycle time, 70% cost reduction, 100% material toxicity reduction, 50% reduction in design cycle time, 10% increase in stiffness, 10% increase in shock mitigation, zero net change in optical stability, zero net change in geometric tolerance, and a 10% weight reduction.

Technical Approach

The TORO program sought to achieve the program objectives using state-of-the-art TO, light weighting, and end-to-end AM processing within the nTop Platform software. The existing nTop platform software provided key advantages in geometry manipulation and design cycle time reduction, such as the ability to go from optimization results directly to slice files. In addition to leveraging existing capability in the nTop Platform, the TORO program planned to generate new capabilities in the software that are applicable to optics workflows. Baseline designs generated by Raytheon Technologies (RTX) were optimized through the new workflows created by nTopology, additively manufactured out of aluminum at RTX, tested by the National Institute for Aviation Research at Wichita State University (NIAR), and iterated to demonstrate improvements in critical performance metrics over a baseline design.

Flowing requirements from defense contractors directly into commercially available software was a strength of this approach, enabling designs to address the critical performance metrics of stiffness, dampening, thermal management and stability, and geometric tolerances for optimizing optical components. New workflows generated within nTop Platform became available to America Makes Membership. These software improvements enabled more cost-effective optical components with reduced lead times compared to conventional design processes.

Accomplishments

The AM process used to produce the mirrors was shown to be in control throughout the project by producing witness coupons with consistent tensile properties. The variable isogrid concept for Prototype 1 was turned into a full design, modified for AM, and analyzed in ANSYS. Upon successful AM, it was shown to be machinable and produced a good surface when diamond point turned. Testing showed stiffness to bolt-up distortion, robustness to vibration, and adherence to the nominal geometry without entrapped powder. Prototype 2 was analyzed and shown to have good performance, although it was heavier and had a higher P-V deformation than Prototype 1. Nevertheless, performance was good compared to the conventional aluminum design, i.e. direct material substitution for beryllium. The demonstration cycle used a hybrid strategy, taking lessons from the first two prototypes and employing additional light weighting strategies. In all three cases, the performance of the optimized mirrors was vastly superior to direct material substitution of aluminum for beryllium. To highlight one specific result, the P-V displacement of the baseline aluminum is 540% larger in gravity sag (load case 1) than that of the beryllium baseline, as compared to 168% larger for the optimized aluminum Demonstrator. Likewise, the mass of the aluminum baseline is 46% higher versus the baseline beryllium, as opposed to the optimized Demonstrator design which has essentially equivalent mass. In addition, the first mode frequency of the aluminum baseline is reduced by 61% compared to the beryllium baseline instead of the 18% reduction of the optimized Demonstrator design. Finally, several of the defined project objectives were exceeded. For example, both cost and build cycle time were significantly improved via the use of AM. The objective for each of these was a reduction of 50%. The final achieved reduction in cost was approximately 65% and in build cycle time was more than 80%.

Project Participants

Project Principal

Other Project Participants

- nTopology

- National Institute for Aviation Research (NIAR)

Public Participants

- U.S. Department of Defense