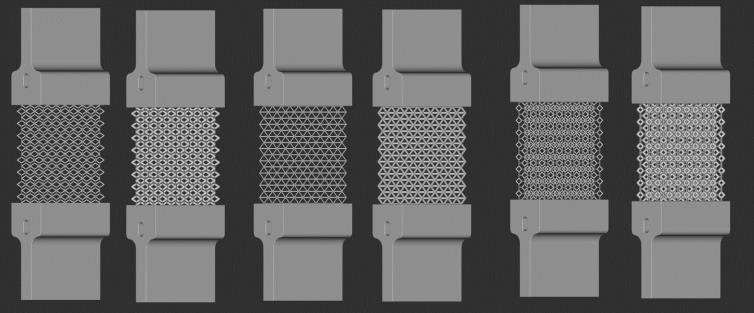

Post-build plate with multiple lattice designs created using nTopology software

Problem

Complex cellular and lattice structures are an exciting field of materials development offering revolutionary opportunities in medical devices, light-weighting, and impact protection. Additive manufacturing (AM) is uniquely suited to produce lattice structures and there has been a synergistic development cycle between the lattice design community and AM. There is, however, an unmet need for a standard approach to mechanical testing and evaluation of these lattice structures to support their introduction into demanding applications for defense and commercial use.

Objective

The objective of this effort was to develop a standard approach to mechanical testing and evaluation of lattice structures. The program sought to deliver an ASTM work item style final report proposing a test geometry and supported with a technical data package including tensile results and digital image correlation (DIC) imaging from a design of experiment (DOE) matrix of lattices.

Technical Approach

The Ohio State University’s Center for Design and Manufacturing Excellence (CDME) led the effort. The technical approach included lattice demonstration geometry created using nTopology, printed in 316L using laser powder bed fusion on a Concept Laser M2, then evaluated using multiple approaches for tensile testing and measured using DIC. The core of the technical approach was defining and measuring the specific dimensions of the tensile bars as a function of lattice unit cell and strut size that produces a low scatter, uniform mechanical evaluation. This technical approach was envisioned to be translatable to other materials such as Ti64 and can be used to develop lattice coupons for compression and shear loading conditions as well. The tensile test geometry consisted of a lattice structure in the gauge section with printed solid material for gripping. The initial geometry was a nominal 1cm x 2cm x 2.5cm gauge section specifically sized so that only complete lattice unit cells were within the gauge section (no partial cells “clipped” at the grip sections) with grips sized to interface with the lattice gauge section. Lattice designs were produced using nTopology software. Samples were printed using a Concept Laser M2 in 316L stainless steel and then stress-relieved before tensile testing with the as-printed surface finish. Mechanical testing was performed using mechanical test frames and 3D DIC hardware and software.

Accomplishments

This program was able to successfully examine a variety of metal-printed lattice designs and develop initial test artifacts to understand tensile properties. Based on initial test data, Ohio State University recommends continuing the development of the rectangular lattice specimen for tension testing as well as finding ways to reduce the size of the ASTM E8 specimen. Further development is needed to create a clear definition for the number of required unit cells as well as further development of gradient lattice structures to shift lattice fractures from the boundary areas to the gauge section. The project team has created a preliminary parametric rectangular lattice model, which was a key deliverable for this project. The nTopology workbook is provided in the technical data package and an image of this can be seen in the final report written. Lastly, the use of 3D-DIC has allowed the project team to understand the failure modes of different gauge sections, grip designs, and lattice unit cell structures.

Project Participants

Project Principal

Other Project Participants

- NCDMM/America Makes

Public Participants

- U.S. Department of Defense