The ability to read and output real-time, high-speed measurements and output scanner positions and laser time was demonstrated. Direct comparison between build plan and high-speed measured data have also been demonstrated using standard coupons. Demonstrations were carried out on a 3D Systems ProX-200 machine.

The project research entailed close collaboration between 3D Systems and PSU ARL, along with Honeywell and Northrop Grumman as representatives of major OEMs, to develop an open protocol that enabled researchers and OEMS to specify and record AM machine behavior, which included scan strategy, beam power dynamics, detailed scan velocity, and other important parameters.

Problem

No standard protocol currently exists that specifies the behavior of, monitoring, or control of powder bed fusion additive manufacturing (PBFAM) systems. Pennsylvania State University – Applied Research Laboratory (PSU ARL) is leading the development of an open, layered protocol, enabling any U.S. manufacturer to access data related to the monitoring and control of PBFAM systems.

Objective

The objective of this project was to develop and demonstrate an open, layered protocol for PBFAM in collaboration with commercial OEMs and a commercial PBFAM systems manufacturer.

The development of this protocol is anticipated to benefit:

- Researchers – by providing access to critical data for modeling and by enabling synchronization of machine data with sensing systems, control, and process optimization;

- Industry – by enhancing qualification and certification efforts; and

- Machine manufacturers – by increasing customer confidence in the process and establishing a vibrant development ecosystem.

Technical Approach

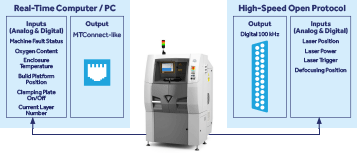

The project research entailed close collaboration between 3D Systems and PSU ARL, along with Honeywell and Northrop Grumman as representatives of major OEMs, to develop an open protocol that enabled researchers and OEMS to specify and record machine behavior, which included scan strategy, beam power dynamics, detailed scan velocity, and other important parameters.

The protocol also enabled real-time recording of process parameters, such as machine scan position, so that these important parameters could be linked to other sensor measurements and information.

Natural extensions of such an effort included the use of this protocol for enabling distributed computing and feedback for real-time control.

Specifically, the project demonstrated the ability to:

- Extract and interpret build path plan data

- Use high-speed data acquisition to obtain detailed laser scanner data

Synchronize machine data to commercial off-the-shelf (COTS) sensors

Accomplishments

All components of the open protocol system were demonstrated on a commercial 3D Systems ProX-200 PBFAM machine. The developed protocol enabled specification and extraction of scan path and communication between a PBFAM system and heterogeneous systems for condition monitoring, data acquisitions, and in-process sensing, which offers significant potential benefits to both researchers and industry.

The open protocol now provides a pathway to access laser trajectory and settings, which together with real-time access to process variables and the integration of in-situ sensors, researchers are now better able to model PBFAM processes.These pathways also enable the development of quality assurance and qualification tools, which are of significant interest to industrial users.

Already, several end users of 3D Systems ProX-200 systems have indicated a great interest in the installation of the open protocol system on their machines and at least one installation is currently being planned.

Additionally, the dissemination of work related to the development of an open protocol system for PBFAM has occurred though conference proceedings, a demonstration workshop, and numerous presentations, including at the 27th Annual International Solid Freeform Fabrication Symposium, SAMPE 2016, and the 22nd International Symposium on Air Breathing Engines. Attendees of the demonstration included officials from America Makes, government organizations, and other industrial members of America Makes.

Project Participants

Project Principal

Other Project Participants

- Honeywell International Inc.

- Northrop Grumman Corporation

- 3D Systems Corporation

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy