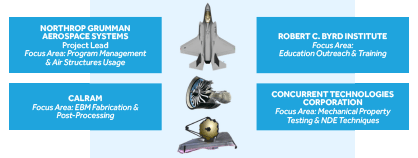

The Integrated Project Team provided expertise in aerospace systems, EBM fabrication, integrative education, training, workforce development, and independent applied research.

Northrop Grumman Aerospace Systems (NGAS) has executed a project for the development of a material allowables database while also demonstrating validation of Non-Destructive Evaluation (NDE) methods on a full scale set of Electron Beam (E-Beam) Powder Bed Fusion (PBF) Additive Manufacture (AM) demonstration components.

Problem

The adoption of electron beam melting (EBM) additive manufacturing (AM) has been limited within military aircraft and space applications. Implementation in airframe, space, and propulsion applications has been directed only to nonstructural, nondurability-rated components primarily for static strength at operating temperatures. There are opportunities for expanding implementation of EBM AM to create structural, durability-rated components which could have a significant impact on cost and surge production needs. Widespread consideration of EBM AM for highly loaded or elevated temperature exposed components would require a statistically significant materials design dataset.Problem Description Goes Here

Objective

The objective of this project was to develop a materials design allowables dataset for EBM Ti-6Al-4V AM material and demonstrate full-scale component fabrication with a surface finish comparable to traditional machining methods. The project also sought to provide validation of nondestructive evaluation (NDE) techniques on the demonstration components.

Technical Approach

The project team led by Northrop Grumman Aerospace Systems (NGAS) leveraged well-understood methodologies, building-block approaches, and transition to production processes previously used in the development and implementation of AM technologies at NGAS.

Static and dynamic tests were conducted in accordance with ASTM specifications. Microstructures were documented using standard laboratory sectioning, polishing, etching, and metallographic inspection techniques.

Direct method analysis was used to calculate the tensile yield strength (TYS), ultimate tensile strength (UTS), and elongation (ELG) allowables. For the direct analysis calculations, the Metallic Materials Properties Development and Standardization (MMPDS) Industrial Steering Group (ISG) Design Allowable Software (MIDAS) program was utilized to calculate the direct allowables per the requirements of the MMPDS handbook. The MIDAS software performed all of the required calculations for the TYS, UTS, and ELG allowables.

The indirect analysis method required all compression, pin bearing, and shear coupons to be matched with a tensile coupon to determine the respective indirect property allowable. Each pair needed to be within the same powder lot and additive build structure. Orientation and thickness were also used as criteria for proper pairing.

Accomplishments

A materials design allowables dataset was completed. Multiple full-scale components were identified, manufactured, and post-processed.

- One variant was media blasted and the second was chem-milled (Ducommun) then finished with a chemically-assisted aggregate (REM).

- First iteration of each full-scale candidate component fabricated per engineering definition.

- Second iteration of each full-scale candidate component fabricated with embedded defects.

- Completed NDE assessment of full-scale components. Utilized size distribution of embedded cylindrical defects for legacy film x-ray radiographic inspection (2-2T sensitivity per ASTM E 1742 Standard Practice for Radiographic Examination).

- Completed coupon fabrication for mechanical properties testing and developed process parameters for 50-micron builds on the Arcam S12, A2, and A2X systems.

- Included extensive powder handling plan and build travelers developed with CalRAM to ensure strict material process control across the 13 powder lots.

- Interrogated build layout, layer time, line lengths, support scheme, machine log files, and total build time in advance of every build.

- Closely monitored and recorded processes and procedures used in the technology development, test, and evaluation to determine skill sets needed for production and manufacture.

- Collaborated with equipment manufacturers to define prerequisite training.

- Reviewed current skill sets and training utilized in EBM and identified any needed modifications for this specific technology.

- Made recommendations for the development of custom and public training.

- Documented procedures to be incorporated into manuals and training guides.

- Provided recommendations for developing AM (specifically EBM) standards

Project Participants

Project Principal

Other Project Participants

- CalRAM

- Concurrent Technologies Corporation

- Robert C. Byrd Institute

- Puris, LLC

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy