The NIST part was used to identify powder systems made workable in Arcam and EOS machines.

This project seeks to identify powder properties needed to characterize powders and demonstrate feasibility of using powder metals other than those from the machine manufacturer.

Problem

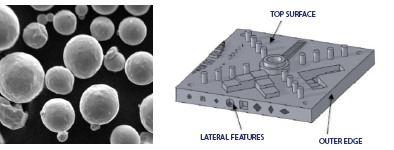

With the rise of powder bed additive manufacturing (AM) processes such as direct metal laser sintering (DMLS) and electron beam melting (EBM), metal powder companies are striving to position themselves as the source for powders to be used in direct metal AM systems. Most metal powders for AM are purchased directly from equipment providers. Current powder production methods are based on the needs of the powder metallurgy industry. Powders have not been developed specifically for AM, so there are limited experimental studies available related to the use of different powders in direct metal AM systems.

Objective

The objective of this project was to create a first-of-its kind database relating powder properties (mean particle diameter, particle diameter distribution about the mean, particle morphology, and metrics for flowability) to process outcomes (spreadability, ability to be sintered, melt pool geometry, microstructure, geometric precision, and material hardness).

Another objective was to identify process variable changes needed to yield outcomes comparable to standard powders for at least one powder system that is not immediately useable in a direct metal machine.

Technical Approach

This project directly targeted the relationships between powder properties and process outcomes. These relationships were explored via the development of an experimental database of different powders used in Arcam and EOS machines, created through round robin tests performed at North Carolina State University (NCSU) and Carnegie Mellon University (CMU).

The database included experimental results from studies including:

- Powder spreadability: the effects of a new powder on how uniformly a powder can be spread is as important as the effects of a new powder on melt pool formation and part building.

- Ability of the powder to be sintered: an issue only associated with the Arcam process, but it is critical. In EBM, the powder must first be sintered before it can be melted and fused.

- Powder melting outcomes: related to how powder differences can change the thermal problem of powder melting, melt pool formation, and microstructure formation upon solidification.

Accomplishments

The project team defined and tested seven powder systems with larger than standard particle sizes, as well as one Arcam and one EOS standard powder system as control. Three powder systems used Arcam EBM and four EOS DMLS.

Three different powder production processes were utilized: Gas Atomization, PREP, HDH+PS. All powder systems were tested at two or more locations.

All seven powder systems were made workable in AM machines. Methods were established for:

- Static powder property measurement

- Powder dynamic (flow) property measurement

- Rapid testing of new powder systems in AM machines

- Changing process variables for new powder systems

A one day on-site training session was developed and held at CMU entitled “Introduction to the EOS M290 Laser Sintering Process and Equipment.” The team worked with Carpenter Powder Products and SAE International to develop content and provide a technical review of the training materials. Training covered an introduction to AM; demonstration part design; close-up look at equipment; setting up the build; the build in progress; introduction to post processing steps; technical discussions with AM faculty; and debrief and feedback.

Project Participants

Project Principal

Other Project Participants

- North Carolina State University

- Allegheny Technologies Incorporated

- 3D Systems

- Carpenter Powder Products

- National Institute of Standards and Technology

- Walter Reed Army Medical Center

- United Technologies Research Corporation

- Robert C. Byrd Institute

- TE Connectivity

- Oak Ridge National Laboratory

- CalRam

- Alcoa

- Ametek

- Fineline

- Timet

- Pratt & Whitney

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy

- National Aeronautics and Space Administration