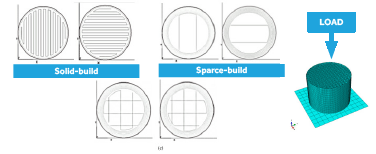

Test coupons were fabricated with three kinds of build functions using the Fortus 400mc machine: solid-build, sparse-build, and sparse-build & double density. Mechanical properties were measured from room temperature and elevated temperature compression and flexure tests. Good agreement was observed between these experimental results and the finite element predictions of these mechanical properties.

This project seeks to determine the feasibility of utilizing sparse-build FDM tooling technology for use in vacuum assisted resin transfer molding (VARTM) and hydroforming to produce rapid tooling while reducing the amount of material required.

Problem

Limited data is available on the performance of tooling components for fused deposition modeling (FDM) solid-build (with near full density), and little data is available for sparsebuild, especially for high-performance thermoplastics such as ULTEM 9085. Data on FDM tooling components made

from ULTEM material for use in high-temperature composite manufacturing and hydroforming processes is extremely limited. Similarly there is little knowledge existing regarding the design of sparse-build FDM tools that could reduce the amount of material while maintaining strength to prevent failure and part deformation.

Objective

FDM is a proven technology in additive manufacturing that holds great promise for fabricating tooling components used in composites manufacturing and sheet metal forming. This study was aimed at producing rapid tooling while reducing the amount of material. The objective of this project was to

determine the feasibility of utilizing sparse-build FDM tooling technology for use in vacuum assisted resin transfer molding (VARTM) and hydroforming.

Technical Approach

The project team investigated the manufacturability of various sparse-build ULTEM coupons with different build parameters using the Fortus 400mc machine to examine how the mechanical properties, including the strength and modulus, are affected by the build parameters. Finite element models for predicting the mechanical properties of 3D parts of any shapes and internal structures were developed and validated. Finally, the feasibility of fabricating solid-build and sparse-build molds/dies by the FDM process and using the fabricated tools for VARTM and hydroforming was examined. The specific project tasks included:

- Fabrication of solid-build and sparse-build test specimens using the FDM process

- Measurement of mechanical properties for the test specimens

- Finite element modeling and analysis to predict the mechanical properties of test specimens verified by experimental results

- Fabrication of solid-build and sparse-build molds/dies for testing in VARTM and hydroforming processes

- Testing of fabricated molds/dies in VARTM and hydroforming processes and analysis of experimental data

Accomplishments

Sparse-build test coupons from ULTEM 9085 material with varying air gap (sparse spacing), wall thickness, and cap thickness were fabricated using the sparse and sparse- double dense functions of a Stratasys Fortus 400mc machine. The strength and modulus of each coupon were measured using compression and flexure tests. The strength/weight ratio and modulus/weight ratio were compared among the various sparse coupons and solid coupons.

Compression and flexure tests were performed at elevated temperatures for sparse double dense ULTEM coupons. Additionally, finite element modeling and analysis were performed to predict the mechanical properties of the test specimens with varying air gap and wall/cap thickness at room and elevated temperatures. Good agreement between simulation and experimental results was observed.

A fully coupled 3D transient thermo-mechanical finite element model was developed to investigate the behavior of both solid and sparse-build ULTEM tools during the VARTM cure process. A nonlinear temperature dependent elasto-plastic material model of ULTEM tool based on the experimental data was developed and implemented in ABAQUS 6.10. Temperature distribution, thermo-mechanical deformation, and stress distribution during the cure process (up to 350°F) were analyzed.

Experimental thermal cycling at two elevated temperatures (180°F and 250°F) was performed, and two sets of 5 cycles each were applied to both solid and sparse-build tools. The dimensional accuracy and surface roughness before and after thermal cycling were examined. The finite element analysis results indicated that sparse-build tools are preferable to solid-build tools as the former not only saves tooling cost but also tends to cause less thermal expansion mismatch between the tool and the manufactured composite part.

Project Participants

Project Principal

Other Project Participants

- Boeing

- Stratasys

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy