Top selected code submissions were used to print geometries from Ti-6AI-4V. These parts were then subjected to predefined evaluation criteria and scored.

Problem

While America Makes has made tremendous progress in advancing open framework software, controls, and equipment with multi-laser metal additive manufacturing (AM), there are still challenges with the proprietary nature of commercial scan strategies. Substantial development of open-source scan strategies is needed to realize improvements in microstructure homogeneity, surface roughness, geometric fidelity, and strength. This challenge seeks to address these issues and create a body of work that can be utilized across the AM industry.

Objective

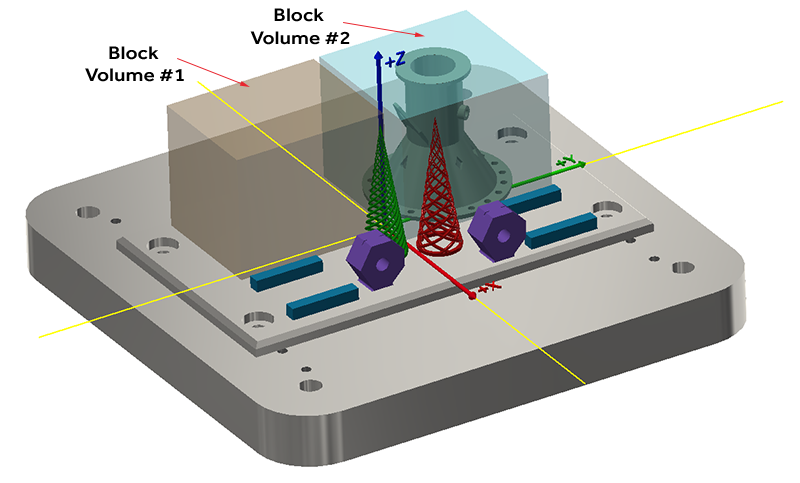

The OASIS Challenge sought to advance the state-of the-art laser-based powder bed AM in temporal and spatial thermal management through the submission of innovative open-source scan strategy codes, algorithms, and/or methods. This was a direct scan strategy challenge to the AM industry instead of a process parameter challenge. All bulk parameters were constrained, and participants were challenged to develop the best methods for scanning each layer of the challenge geometries.

Technical Approach

This project challenged the brightest minds from industry and academia to utilize open-source software developed in America Makes Project 4039 entitled “Development and Demonstration of Open-Source Protocols for Powder Bed Fusion Additive Manufacturing (PBFAM)” to advance the technology of opensource software and machine platforms. A down-selection process of the submitted codes was conducted according to a series of quantitative metrics for ranking the submissions and identifying the best codes. America Makes worked with Global Research (GEGR) to utilize the few “top selected” scan strategies to produce physical samples on the M2-Open Direct Metal Laser Melting (DMLM) machine developed under America Makes Project 3024 entitled “Acceleration of Large-Scale Additive Manufacturing (ALSAM).” Samples were evaluated using a set of relevant evaluation/ inspection criteria. Cash prizes up to $25,500 were awarded. The results and associated data were then integrated into the America Makes National AM Roadmap and the Digital Storefront.

Accomplishments

The benefits of scan strategy optimization were demonstrated for a variety of complex geometries produced via laser powder bed fusion of Ti-6Al-4V. Submissions by challenge participants applied different process control algorithms leveraging an opensource process controller which demonstrated desirable effects on common metrics critical to AM product quality including as-built geometry, surface roughness, microstructure, and mechanical properties.

Project Participants

Project Principal

Other Project Participants

- GE Global Research (GEGR)

- Air Force Research Laboratory (AFRL)

Public Participants

- U.S. Department of Defense