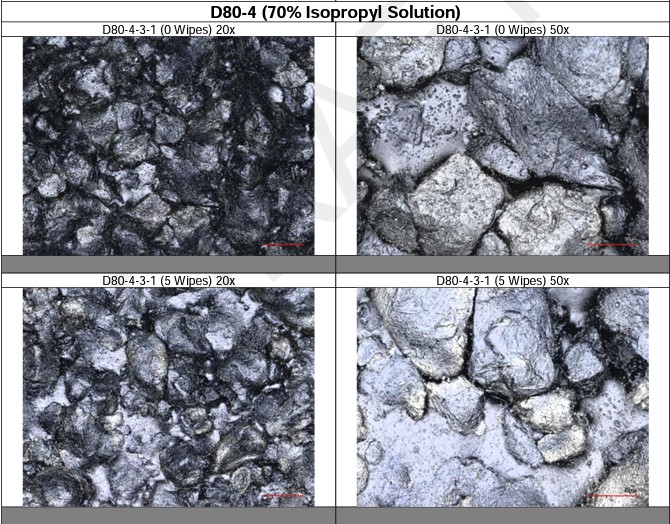

Microscopic analysis of polymer material exposed to isopropyl solution.

Problem

The pandemic outbreak of the COVID-19 virus caused a global concern for public safety and the necessity to expand cleaning and sanitizing procedures. This increase in sanitizing measures also sparked a new concern for the effect that different sanitizing chemicals play on material degradation after extended or recurring exposure. To evaluate the material response from extended exposure to cleaning solutions, mechanical test data was needed considering a range of sanitizing agents and exposure conditions.

Objective

This project was developed to run concurrently with the Service Life of Additive Manufacturing (SLAM) Advanced Tools for Rapid Qualification (ATRQ) project as a response to COVID-19 public health concerns. The objective of this effort was to study the effects of sanitizing chemicals on additively manufactured polymers through material inspection for surface analysis and mechanical testing after sanitizing solution exposures. FR106-4, D80-4, and PA12-2.6.7 were the different materials tested for this response program.

Technical Approach

The project team performed three (3) main tasks during the project effort. These were fabrication, chemical exposure and analysis, and mechanical testing. The NIAR team fabricated the required material types to satisfy the test matrix for chemical exposure/analysis and mechanical testing. Specimens were fabricated per geometry requirements of ASTM D638 Type 1 in a consistent manner between materials. The team subjected each material type to varying chemical exposures to different chemical solutions and durations of exposure. A baseline set of unexposed specimens was kept for comparison to the tested samples. The team also performed FTIR (ATR) scanning at set intervals of sanitizing solution exposure to evaluate the effects on material composition. Microscopy analysis of the material surface was conducted at set intervals to capture profilometry and remaining chemical residue or degradation. Lastly, the team mechanically tested all chemically exposed samples to supply tension data for varying exposure durations, methods, and chemical solution types.

Accomplishments

The observations made from the sanitizing chemical exposure analysis provided some insight into the effects of cleaning solutions on additively manufactured (AM) polymer materials. Mechanical performance evaluations further developed an understanding of how extended exposure to a chemical solution affects the characteristics of a material. Chemical exposure analysis showed that there was no deviation from the baseline sample for most specimens across all three materials tested. Microscope imaging was performed at set intervals of sanitizing chemical exposure including inspection at 5, 25, 50, and 100 wipes along with an unexposed analysis and a 24-hour immersed soak sample. This interval inspection was performed for all material and sanitizing chemical solution combinations to supply a full record of surface effects that cleaning solutions have on AM materials. As a result of this extensive testing, the project team was able to successfully complete their goal of determining how sanitizing chemicals affect materials used in additive manufacturing.

Project Participants

Project Principal

Other Project Participants

- NCDMM/America Makes

Public Participants

- U.S. Department of Defense