The laser powder bed fusion process requires testing and validation to establish surface finish, porosity, and thin section build effects.

Problem

Wrought material properties of Inconel 718 (IN718) are well known; however, the material properties of thin section components utilizing the laser powder bed fusion (LPBF) additive process are less known—specifically, property enhancement obtained through hot isostatic pressing (HIP). The HIP process has long been a standard practice, as opposed to a well-understood requirement, for the manufacture of flight components. The development of a quantitative understanding of the HIP process, could provide a better understanding of the cost-benefit analysis of additively manufactured (AM) flight parts, and accelerate adoption for reductions in costs and lead times.

Objective

The objective of this program was to expand the knowledge base of mechanical properties for thin sections in components produced by LPBF in IN718, including the effects of HIP. The project sought to understand the underlying morphological and/or microstructural mechanisms to enable implementation into finite element analysis (FEA) software. Understanding these mechanisms would encourage the use of LPBF for flight components through the development of quantitative material data (e.g., static and fatigue strength, density, etc.) through analysis and testing, and integrating these findings into FEA software through the creation of an ANSYS Workbench file.

Technical Approach

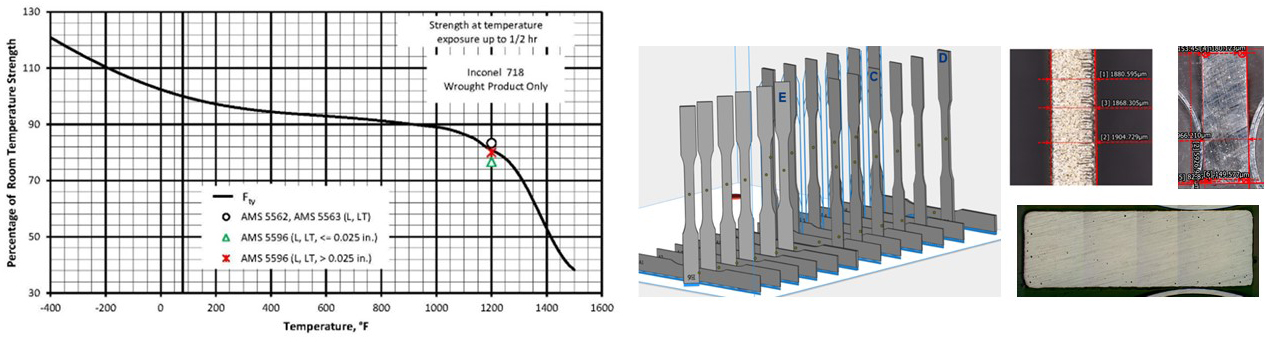

Arizona State University led the effort which included Phoenix Analysis and Design Technologies, Quintus Technologies, and Phoenix Heat Treating, Inc. The technical approach was to design and build test specimens for analysis and testing. The quantitative data was integrated into an FEA package, which was then qualified through modeling and comparison to honeycomb compression testing, previously conducted outside of this project. Chronologically, a specimen was designed, taking into consideration build, analysis, and testing needs. The parts were built (with a Concept Laser M2), stress-relieved, and removed from the build plate. Half of the pats were HIP’d and all parts were then heat treated following AMS5663 procedure. Computed tomography was used to obtain porosity, grain size, and orientation; a Keyence VR3200 scanner measured surface roughness; dimensional analysis was conducted utilizing a blue light scanner; density values were then obtained; static and fatigue strength testing was conducted utilizing ASTM E466 standards and an Instron 8801 machine; and ASTM E8 standards and an Instron 5989 machine were used for determining modulus strength. Finally, modeling and validation were conducted through honeycomb compression modeling utilizing an ANSYS Workbench file created for the FEA analysis, utilizing the qualitative information from the project.

Accomplishments

The work established if and what mechanical property debits to Yield Strength, Ultimate Tensile Strength, Elastic Modulus, and Elongation were seen in thin wall behavior for LPBF Inconel 718 as a function of wall thickness and HIP condition. Three test environments included:

Quasistatic Room Temperature:

- Elastic modulus shows no clear thickness dependence.

- Yield strength only shows thickness dependence for the non-HIP condition.

- Ultimate tensile strength shows reductions with thickness below, for both HIP and non-HIP specimens.

- Elongation shows reductions with thickness below 0.75mm, and this is true for both HIP and non-HIP and AM and sheet metal specimens.

Quasistatic High Temperature:

- Elastic modulus and yield both show degradation with temperature, with particular drops seen for yield strength at and below 1400 F.

- Elastic modulus does not show consistent thickness dependence at all temperatures.

High Cycle Fatigue:

- HIP metal AM specimens showed good agreement with the baseline non-HIP sheet metal AM specimens.

- HIP specimens had higher fatigue lives at high stresses, but lower lifetimes at low stresses.

Elastic modulus, for non-HIP specimens, showed sheet metal specimens have higher elastic modulus than AM, with HIP reducing these differences. The yield strength for AM specimens had higher yield strengths than sheet metal. Ultimate tensile strength (UTS) showed similar trends as yield strength with AM specimens, with the reverse true for sheet metal specimens. Elongation showed similar trends for AM and sheet metal.

Project Participants

Project Principal

Other Project Participants

- Phoenix Analysis and Design Technologies (PADT)

- Quintus Technologies

- Phoenix Heat Treating, Inc.

Public Participants

- U.S. Department of Defense