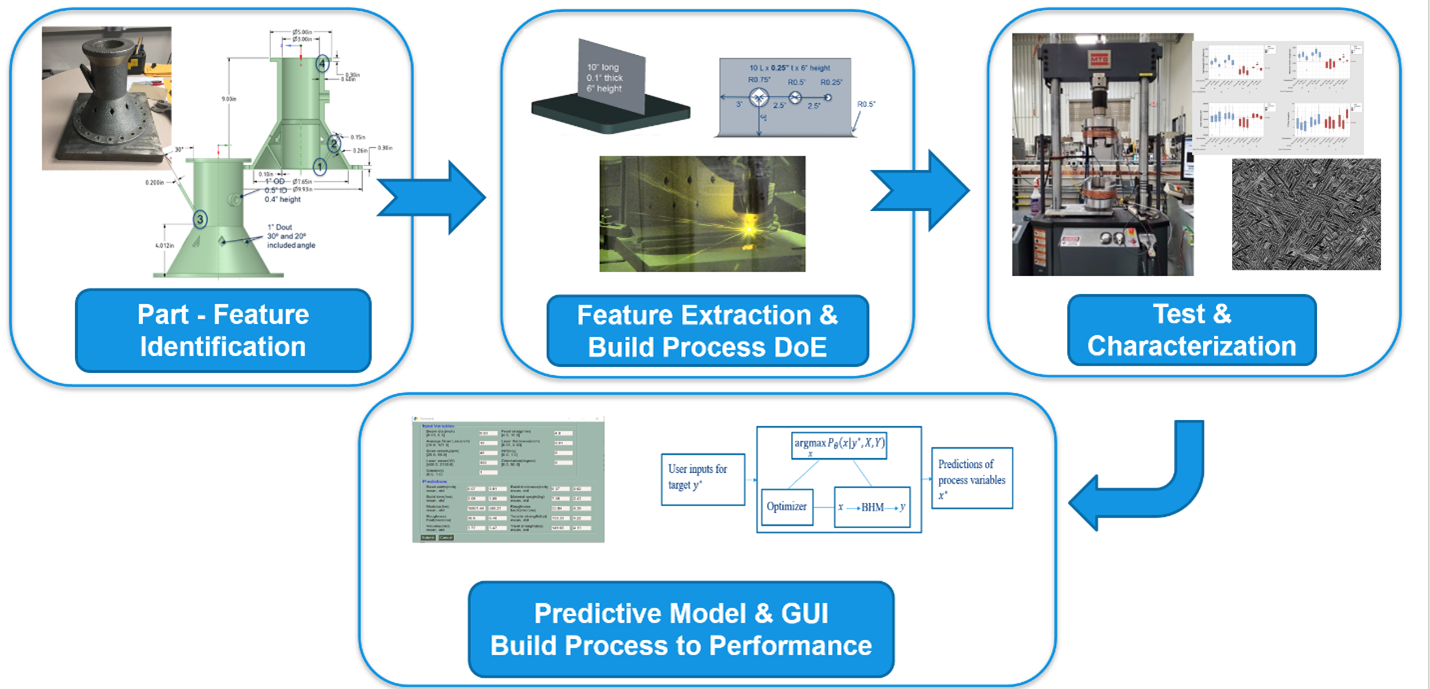

Example of a feature-based qualification approach where the results of the mechanical testing and metallurgical characterization are utilized to train a Bayesian Hybrid Model for the prediction of the feature’s tensile properties.

Problem

It can take several years to go from concept to production for components produced by additive manufacturing (AM). The flexibility of the AM process allows for build customization including build strategy and process conditions. This can lead to long iterative evaluation cycles—printing parts, post-processing, dimensional inspection, material performance, and functional performance—which greatly increases the time and cost of substantiating the process and component.

Objective

The objective of this project was to improve the speed and confidence of directed energy deposition (DED) process qualification by identifying application space, process technology, and materials; developing and validating feature-based build qualifications (FBQ) by cataloging features, build process parameters, and material property relationships; and deploying the FBQ Bayesian Hybrid Model approach to accelerate design engineering and process qualification.

Technical Approach

GE Global Research Center (GEGRC) developed FBQ by first identifying part-based critical features (including engineering and performance requirements), testing protocols, and printing specimens, thus establishing additive characteristics and performance measurements. In addition, probabilistic modeling and efficient sampling were developed for a performance catalog based on FBQ methodology.

GE Bayesian Hybrid Modeling framework (GEBHM) in conjunction with Intelligent Design Analysis of Computer Experiments (IDACE) was used to build predictive models of each feature for the relationship among process parameters, additive build characteristics, and material performance. Implementation efforts included defining the application space, process technology and materials; generating hybrid probabilistic models relating feature performance to process; and deploying hybrid models to the engineering community. Training development and pilots were also planned.

Accomplishments

The team developed and successfully demonstrated the feasibility and accuracy of a probabilistic artificial intelligence/machine learning (AI/ ML) driven feature-based qualification framework for Ti64 DED builds. The approach offers the potential for 60 to 85% savings in fabrication and characterization costs compared to traditional qualification approaches. The model demonstrates the merits of AI/ML approaches for prediction of various feature tensile properties as well as the ability to prescribe process parameters for achieving a desired tensile property. This solution is applicable to a range of geometric features and can be a useful tool for accelerating development and qualification of metal AM products. A copy of the executable and all of the compiled data for the model is available to America Makes members. The team developed and delivered a video training course on their method and model which includes a detailed step-by-step guide on the feature-based qualification framework and a model user reference guide.

Project Participants

Project Principal

Other Project Participants

- Raytheon

- EWI

- Youngstown State University

- GE Aviation

Public Participants

- U.S. Department of Defense