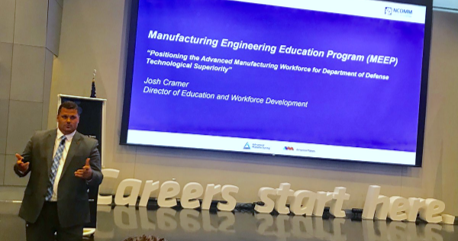

America Makes EWD Director Josh Cramer addresses members during a presentation held during a Technical Review and Exchange (TRX) Conference.

Problem

Domestic manufacturing is critical for our national defense. Jobs availability in the manufacturing engineering and technical workforce and overcoming the barriers of successful manufacturing technology transition are critical for our nation’s economic and manufacturing strength. To ensure that a strong defense industrial base is ready and accessible, a trained and skilled workforce is required.

Objective

The Manufacturing Engineering Education Program (MEEP) addresses the need to better position the workforce to produce military systems and components that ensure technological superiority for the Department of Defense (DoD). MEEP identifies and fills gaps in training, scales the program nationally, and tailors locally to address diverse needs. MEEP also focuses on advanced manufacturing technologies such as AM and associated enabling technologies at the technologist/technician level.

Technical Approach

The National Center for Defense Manufacturing and Machining (NCDMM)/America Makes, with partners The Society of Manufacturing Engineers (SME) and Thomas P. Miller & Associates (TPMA), addressed this challenge by leveraging its manufacturing expertise and broad knowledge of advanced manufacturing along with a trusted network of partners to solve the workforce training challenges facing the defense manufacturing supply chain.

Working with partner Tooling U-SME, the team leveraged proven methodologies to fill gaps in training, nationally scale a program, tailor locally to address geographically-diverse needs and work to increase the capacity of the country’s workforce in advanced manufacturing technologies such as AM, as well as machine learning, intelligent sensing and design optimization. MEEP assets live on the America Makes Education and Workforce Development (EWD) Roadmap to allow teams to leverage MEEP assets for scale in multiple projects. Promotion of the assets by the project team continues through a variety of digital communication platforms, speaking engagements and national events.

Accomplishments

The sustainability and success of MEEP have revolved around partner collaboration. For example, the use of Tooling U-SME allows access to all individuals within reach, in addition to the America Makes membership portfolio and industry partners. Tooling U-SME continues to offer eLearning courses via subscription access. They employ national sales and service teams supporting companies using Tooling U-SME assets by aligning content with need.

- Regional and national workshops hosted with 7 focus regions across the nation strategically chosen based on underserved populations, veteran populations, and DoD saturation.

- Over 40 industry-recognized credentials and competencies assessed over a wide range of entities.

- Developed and validated Body of Knowledge (BoK) and Competency Model and minimum criteria for certification for SME’s CMfgE/CMfgT programs.

- eLearning Class Development of 33 courses (approx. 25-40 minutes) released to the public (assigned over 90,000 times to nearly 9,000 unique students).

- Developed two instructor-led training courses aligned with technical topics.

- Developed and operationalized updated assessment mechanisms for the Additive CMfgT and CMfgE.

- Conducted workforce and education outreach via customized communication platforms.

- All assets related to usage and sustainability launched to market.

Driving on the mission of America Makes EWD, the team has leveraged best practices from the MEEP project into several scale-up programs. One example was an effort funded by the National Institute of Standards and Technology (NIST) and partially through the CARES Act. This program scaled the reskill and upskill training assets created through MEEP to over 1,000 incumbent workers across more than 100 companies in 48 states.

Another example is through a number of Defense Manufacturing Communities, the Office of Local Defense Community Cooperation (OLDCC), and their Defense Manufacturing Community Support Program (DMCSP). EWD has been able to scale the instructor-led training with Optimizing for Additive Manufacturing as well as Managing a Smart Manufacturing Facility. The programs have reached dozens of industry professionals.

Project Participants

Project Principal

Other Project Participants

- Society of Manufacturing Engineers (SME)

- Thomas P. Miller & Associates (TPMA)

Public Participants

- Office of Naval Research (ONR)