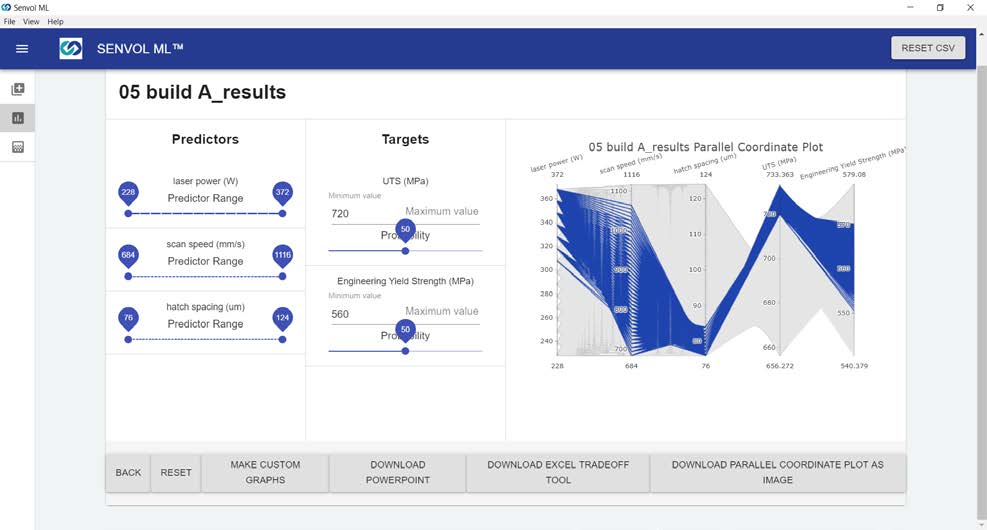

Screenshot of the Senvol ML software; the parallel coordinate plot on the right shows the range of laser power, scan speed, and hatch spacing an AM user could utilize.

Problem

Additive manufacturing (AM) enables lightweight and rapidly produced designs that are revolutionary to defense and commercial capabilities and applications. These benefits cannot be fully realized due to the time and high cost of design allowables development. Design allowables are statistically determined materials property values derived from test data. They are used to establish design limits of stress, strain, or stiffness that are allowed for a specific material, configuration, application, and environmental condition. Material design allowables development requires an enormous amount of empirical data to be generated (costing in excess of $2M over 24+ months), and is a point solution, meaning that all the empirical data must typically be regenerated from scratch every time there is a major change in the process.

Objective

The primary objective of this project is to develop two mechanical property design allowables for AM using a single set of empirical data. This project aims to establish an approach to AM design allowables that leverages the digital nature of AM as well as machine learning (ML), a modern data analysis approach that has been effective in other industries. An ML approach is extremely flexible and able to handle any change to the AM process (e.g. changing AM material or machine), which makes this approach ideal for long term sustainment.

Technical Approach

Senvol plans to apply its existing ML software capabilities to develop a build plan which generates a body of empirical data for analysis. Specifically, two different data sets are being generated during project execution. The first data set is being used as ML training data from which an infinite number of design allowables could be developed using ML approaches. From this single training data set, two different design allowables are being developed using ML, each with its own optimized parameter set. The second data set is being used to develop two different S-basis design allowables using the conventional “point solution” approach. A comparison of time and cost for generating the first and second data sets is being conducted in order to demonstrate that a design allowable approach that leverages ML is both more cost effective and flexible than the conventional “point solution” approach, which is the status quo in industry today.

Project Participants

Project Principal

Other Project Participants

- Northrop Grumman Corporation

- Stratasys Direct Manufacturing

- National Institute for Aviation Research

- Pilgrim Consulting LLC

Public Participants

- U.S. Department of Defense