Using accurate and reliable software to predict distortion caused by thermal additive processes allows drastically reduced product development times and shortened time to production.

Development and validation of physics-based thermal distortion prediction and compensation methods to mitigate distortion in build geometries when using metal powder-bed additive manufacturing processes.

Problem

One of the fundamental challenges in metal powder bed additive manufacturing (AM) is distortion mitigation. Distortion is caused by rapid solidification rates, severe temperature gradients, and temperature-dependent phase transformation. The ramifications of such distortion is that 10 to 15 iterations, or builds, are often required before a CAD model can be turned into a geometrically accurate part.

The project team independently evaluated and concluded that existing commercial off-the-shelf (COTS) software packages are inadequate for simulating the thermal effects of AM processes and consequently cannot be used for high-fidelity distortion predictions in a reasonable time frame (i.e., less than a day).

Additionally, existing physics-based tools that are capable of virtually predicting and mitigating distortion are too computationally intensive for practical use.

Objective

The key objective of this project was to validate and help mature tools for simulating distortion in powder bed AM with the anticipated outcome of reducing the number of iterations typically generated in the creation of a part that meets dimensional requirements. At the start of the project, there was no commercial tool targeted to simulating distortion in powder bed processes available. In fact, distortion compensation tools for AM were just being developed and were not well validated.

Technical Approach

A collaborative team of three, highly technical, and competitive aerospace OEMs—GE, Honeywell and United Technologies Research Center (UTRC)—worked together with software developers 3DSIM, Pan Computing, and CDI Corporation to:

- Execute single-bead trials for understanding laser-particle interaction and for fine-tuning the models.

- Measure powder and as-built thermal and mechanical properties needed for use in simulation tools for the three Inconel alloys (IN625, IN718, and IN718+).

- Develop and build canonical geometries for use in validating the distortion tools.

- Use Coordinate Measurement Machine (CMM) data for distortion tool validation and geometry compensation algorithm.

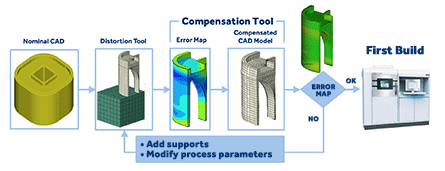

- Develop of a geometry compensation tool based on measurement data and using scaling factors.

- Integrate distortion and compensation tools to develop accurate compensated geometry.

- Create and complete a wiki that allows unfettered data exchange between project participants.

Accomplishments

The project team successfully developed specific geometries (canonical geometry, airfoil, bridge with five supports, and C-section arch) for validating the distortion and compensation tools.

Two of the software tools that were evaluated and validated during the project— Autodesk Netfabb (formerly a product of Pan Computing) and 3DSIM—are now commercial offerings that provide the ability to simulate and mitigate distortion. A third tool, from ESI, is currently in the beta

development stage.

The compensation tool developed by GE is now available for free to America Makes members without licensing requirements.

Additionally, a comprehensive high-temperature thermal and mechanical material properties database for three Inconel alloys (IN625, IN718, and IN718+) was developed.

An ASM training session for ASM and America Makes members was also organized at the University of Louisville, tailored to thermal and mechanical simulations of the additive process. Training documents are available to America Makes members via the Digital Storefront.

In summary, complex geometries that once required up to four weeks to analyze can now be completed within a day. The compensation tool was shown to be capable of being used iteratively to ensure design dimensional requirements are met before the first build. As a result, the number of trial builds was reduced by 75%—from as many as 15 builds down to two or three, thereby greatly reducing the time and cost to develop a new part and optimizing material usage.

Moreover, the project has spurred interest from other software vendors which are now developing comparable tools, using the geometries and data developed during this program.

Project Participants

Project Principal

Other Project Participants

- United Technologies CorporationUnited Technologies Corporation

- Honeywell International Inc.Honeywell International Inc.

- Pennsylvania State University (ARL)Pennsylvania State University (ARL)

- University of Louisville

- CDI Corporation

- Pan Computing LLC

- Autodesk, Inc.

- 3DSIM, LLC

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy