The hybrid concept incorporates additive manufacturing (AM) on familiar CNC platforms, expanding the use of AM by making it available on a conventional machine tool.

This project enables broad proliferation of metal additive manufacturing (AM) through the development of a modular, cost effective LENS® Engine for metal AM, which can be installed in virtually any modern machine tool.

Problem

Adoption of metal Directed Energy Deposition (DED) technology has been hindered by the difficulty of integration into existing production methods. In addition users must learn a new operating system, controller, and methods. Metal DED systems have been developed and commercialized by several companies such as the Laser Engineered Net Shaping (LENS®®) machines from Optomec. While the LENS® technology has matured since its inception in the 1990s and is now generally accepted as a leading method to repair high-value metal components and to build large custom components, broad-based market acceptance has been hampered by its variances from modern machine tool operating platforms and by high equipment and operating costs.

Objective

This project aimed to develop a LENS® Engine that would be self-contained and machine tool agnostic. It would be able to integrate with any reasonable production machine tool (such as a mini-mill, a 5-axis mill, vertical or horizontal machining center, lathe, or other CNC machine platforms, as well as robots).

Technical Approach

Utilizing experience from Optomec’s Aerosol Jet Print Engine, the project team developed a LENS® print engine head, associated powder feeder, and software to allow integration into a legacy CNC machine tool that was retrofitted with updated motion and controls. The system was assembled at MachMotion where initial testing was performed. The equipment was then shipped to TechSolve for additional testing. Control software tools were developed and installed and the machine output was validated. The project successfully demonstrated that the LENS® Engine could be fully integrated on a familiar CNC platform.

Accomplishments

The project demonstrated the practical viability of the LENS® engine modular concept, enabled it to be mechanically integrated into conventional machine tools and provided intuitive toolpath generation to the user.

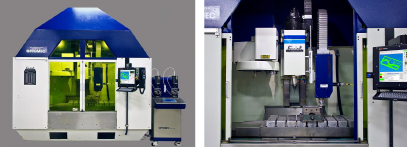

Optomec teamed with Industrias Viwa in Mexico to create a fully integrated product. Their first hybrid machine “Powered by Optomec’s LENS® Engine” was built in March 2016 and demonstrated at the ExpoMaq trade show in Mexico in April 2016 and Rapid in Orlando in May 2016.

Optomec has enabled both of its OEM collaborators (Viwa and Fryer) to offer their own “Optomec Powered” adaptations of their products.

The hybrid concept is viewed as a stepping stone for the potential adopter of additive manufacturing who doesn’t need to go “all in” for a high-cost system. This project successfully demonstrated how the LENS® Engine can be fully integrated on a familiar CNC platform.

Project Participants

Project Principal

Other Project Participants

- MachMotion

- TechSolve

- Lockheed Martin

- Benet Labs

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy