The ability to seed representative surrogate defects into otherwise nominal material can provide fundamental understanding of mechanical performance debits and critical flaw sizes necessary for LPBF process and nickel alloy 718 material qualification.

Problem

Laser powder bed fusion (LPBF) has shown significant promise in creating complex component geometries manufactured with several useful metallic alloys. Understanding the mechanical performance of these components, however, still lags traditional processing methods, especially in fatigue and fracture. Mechanical performance debits can be significantly affected due to defect formation during the AM process and post-processing. However, not all discontinuities are defects. Defects in this sense are unacceptable discontinuities that significantly diminish material performance below some design requirement threshold or are not readily detectable through common inspection methods. Understanding the formation of material/processing defects in LPBF and their effect on performance is critical to advancing analysis and model-based qualification methods.

Objective

The objective of this program was to quantify the impact of defects in LPBF with a controlled and systematic evaluation of material performance as a function of defect characteristics in nickel alloy IN718. Specifically, the program sought to develop an understanding of the mechanisms that trigger defect types commonly observed in LPBF; a processing approach to intentionally generate surrogate defects; targeted CT inspection, metallography, and fatigue testing responses of these surrogate defects for comparison to naturally occurring defects; a component scale demonstration of the methodology; and an initial implementation of a software tool for generating build files for controlling defect type, size, and location.

Technical Approach

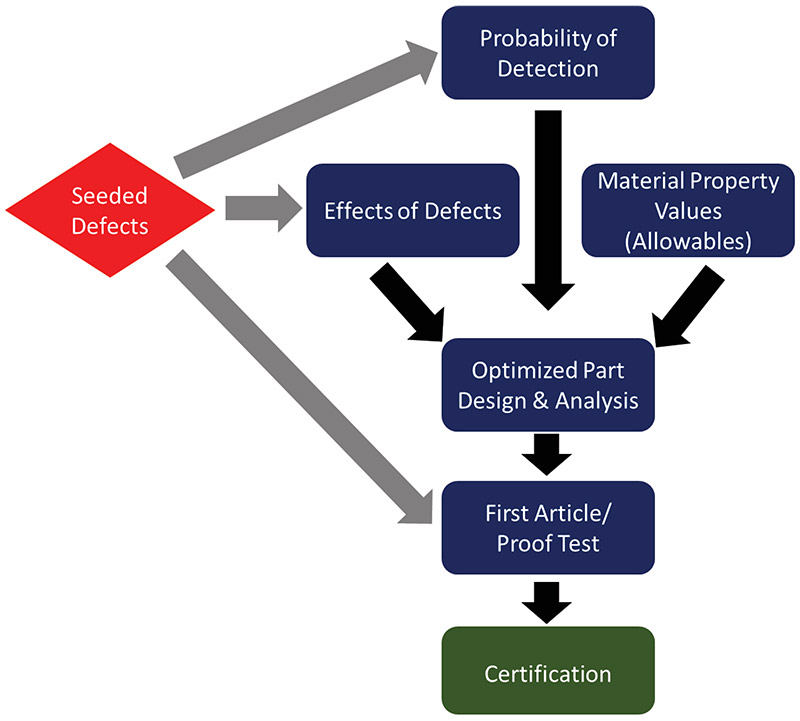

To develop this fundamental understanding of processing defects with LPBF, it was necessary to generate representative defects in a controlled manner to enable quantitative studies of the mechanical property debits and probability of detection (PoD) of authentic LPBF defects. The technical approach and methodology included over a dozen LPBF build iterations in IN718, model-informed analysis of local processing conditions, in-situ process monitoring, post-build computed tomography (CT), mechanical testing (fatigue), and user-developed LPBF fusion machine control. Combining process modeling with in-situ monitoring accelerated the determination of key process parameters needed to control the formation and severity of typically observed LPBF defect types. CT and mechanical testing were used to verify the presence of morphologically representative defects, as well as benchmark their mechanical performance debits relative to legacy data. Ohio State University (OSU) has demonstrated its ability to control numerous key processing parameters to achieve desired material response (high density) in the ongoing #3014 America Makes project. The scope of this program acted as a continuation to elicit the opposite result in otherwise quality material. To ensure the transition to America Makes and the DoD supply chain, OSU partnered with a local small business AM supplier, Proto Precision Additive, and large aerospace and defense OEM/ Propulsion Supplier Rolls-Royce and Lockheed Martin.

Accomplishments

The project team demonstrated the ability to embed multiple classes of defects that have been seen to occur naturally at controlled locations within otherwise nominal material. The team completed a first-order effect of defects study that included tensile, low cycle fatigue, and high cycle fatigue, which showed limited impact on the embedded defects for this material system. Another success was that the team performed a CT inspectability study for embedded defects within coupon and full-scale components. Results showed that CT is sufficient to detect the defect classes focused on in this work in both coupons and full components. All data associated with builds, testing, and inspection have been delivered for further analysis. The data is provided as images, CT scan reconstructions, tabulated mechanical test results, in-process monitoring data files, and build input files and are made available through the Digital Storefront (DSF).

Project Participants

Project Principal

Other Project Participants

- Rolls-Royce Corporation

- Proto Precision Manufacturing

- Lockheed Martin

- Blue Quartz

Public Participants

- U.S. Department of Defense