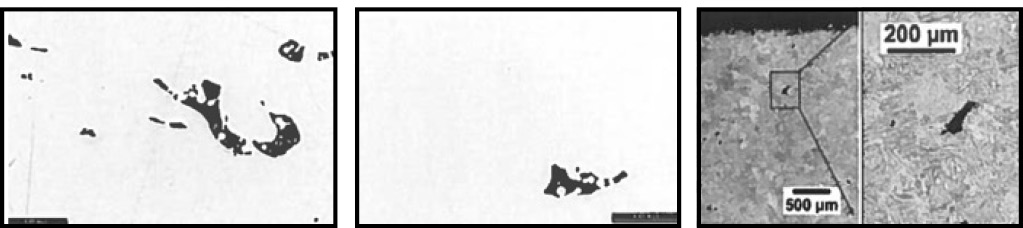

Examples of lack of fusion stochastic flaws observed in Ti-6Al-4V powder bed fusion additive manufacturing builds, post-build, and post-HIP.

Problem

Stochastic flaws are observed in components produced by powder bed fusion additive manufacturing (PBFAM). The naturally occurring flaws are sometimes referred to as rogue or random flaws due to their seemingly random occurrence, even under optimized processing conditions. Stochastic flaws negatively impact fatigue properties, limit the ability to define design limits, hamper qualification efforts, and thus prevent widespread use of AM in many critical applications. To date, little is known regarding the probability of stochastic flaw formation, dependencies on primary and secondary process variables, and the impact of such flaws on fatigue properties.

Objective

The objective of this project was to explore the relationships between PBFAM processes, the generation of stochastic flaws, and the subsequent impact such flaws have on fatigue properties. An additional goal was to systematically examine specific factors expected to contribute to the likelihood of formation of stochastic flaws through targeted experiments that couple comprehensive process monitoring with high-speed video. A final objective was to refine a physics-based model for flaw formation to account for lessons learned from this project.

Technical Approach

The technical approach was to develop statistically significant, pedigreed fatigue data for more than 150 Ti-6Al-4V components. Fatigue testing was performed on the samples and then scrutinized via fractography, metallography, and examination of CT scans to quantify the impact of flaw characteristics on fatigue results. Components were tested using an R-ratio of 0.1, subject to recommendations from industrial partners and the DoD sustainment community. Components were evaluated to assess the influence of virgin versus heavily reused powder, and the PBFAM system itself.

Since the investigation targeted stochastic flaws rather than intentionally embedded flaws, all processing utilized OEM-recommended process parameters. Natural build variations arising from changing location on the build plate and/or build density were also explored. Since most fatigue-limited structures are used in critical applications, all samples were HIP’ed prior to testing. Consistency in the post-process thermal treatment also reduced variability in microstructure, allowing focus to remain on the effect of flaws. Specific factors expected to contribute to formation of stochastic flaws, (e.g. powder thickness variations, contour-hatch, and hatch-hatch overlap regions, scan direction relative to gas flow, etc.) were systematically studied through targeted experiments that coupled comprehensive process monitoring with high-speed video and post-build CT scans to gain insight into the nature of stochastic flaw generation.

Accomplishments

The project team developed statistically significant, pedigreed fatigue data by varying the PBFAM platform and powder feedstock used. In all, 486 fatigue coupons were produced across six builds on two machines with virgin and reused powder, of which 150 were subjected to comprehensive analysis and fatigue testing according to ASTM E466. Analyses included in-situ process monitoring with a range of sensors, pre-HIP (and limited post-HIP) XCT scans, metallography, and fractography. All data were correlated to fatigue performance to generate statistically significant relationships between process conditions (PBFAM platform, powder condition, component location, etc.), the resulting flaw populations (flaw density, flaw morphologies, flaw locations), and fatigue performance.

The team utilized an RTX physics-based PBFAM process simulation tool to predict different flaw types generated during the deposition of Ti-6Al-4V samples and to develop process maps as a function of operational conditions. The tool prediction was used to inform experiments to bolster the understanding of flaw generation. The stochastic modeling approach was established to predict process parameter combinations that produce Ti-6Al-4V parts with fewer defects.

Several manuscripts were prepared for journal publication based on the program results, one of which has already been published in the Additive Manufacturing journal.

Project Participants

Project Principal

Other Project Participants

- 3D Systems, Inc.

- Moog, Inc.

- Oerlikon, Inc.

- UTRC

Public Participants

- U.S. Department of Defense

- National Science Foundation

- U.S. Department of Energy