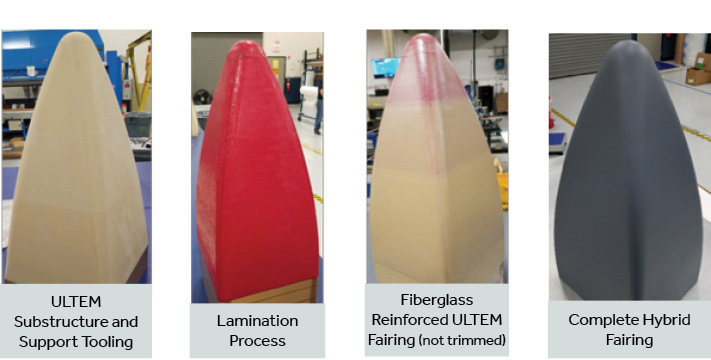

The hybrid nose cone fairing is designed to utilize a flyaway additively manufactured substructure to support the fiberglass skins during the fabrication process and stiffen the flyaway part. These images show various stages of the fabrication process.

Problem

For flight tests and/or singular repairs, additive manufacturing (AM) has proven invaluable for fast and relatively inexpensive substitutions versus traditional manufacturing. This project addresses the reduction of lead times and cost savings offered by AM in a broader application space by reducing the nonrecurring expenses of point design and developing a capability for part families.

Objective

production of AM aircraft fairings into a family of parts solution. The focus was on the hybrid AM approach of composite sandwich panels that could lead to the production of aircraft semi-structural fairings without the need for tooling. In this approach, the underlying fused deposition modeling (FDM) structure and printed Ultem 9085 core acted as the tool for layup of the composite skins, eliminating the tooling costs, minimizing the touch labor from layup and cure, and ultimately reducing the manufacturing span time and the overall cost of semi-structural fairings. This approach was a game changer for the aerospace industry and has the potential to significantly reduce costs for Air Force flight platforms.

Technical Approach

The focus of this project was on B-52 weapon pylon fairings as demonstration articles. The design and development of the hybrid approach included choosing fairings and related parts where sustainment issues exist; identifying flight requirements for these parts; modeling to demonstrate adequate design details for the hybrid composite panels to withstand the flight requirements; fabricating test coupons; performing mechanical and environmental testing to verify part property and performance requirements; and applying AM capabilities to produce and test flight worthy composite fairings. The lessons learned from the B-52 pylon fairing family of parts were then transitioned to a larger part family set of composite sandwich panel aircraft fairings.

Accomplishments

The project work proved that using an integral interior tool structure created by AM with a typical composite layover process can save time and money over the standard manufacturing methods in use. A process was developed to reinforce polymer additive parts with composite face sheets for fairings applications. This hybrid process was used to create several B-52 fairing parts including an HSAB nosecone, an SUU pylon fairing, and several sizes of finlets representing these parts for an EC-130J aircraft. All of these polymer parts replaced existing sheet metal manufactured parts and demonstrated lead time reductions of 50% while reducing the overall part cost by as much as 75%; and for the finlets, provided a weight reduction that could improve aircraft performance. The nosecone and the pylon fairing parts met the required proof testing that consisted of burst and crush pressure-at-temperature strength and dynamic sonic fatigue loading to verify adequacy for flight testing. The results of this study proved that low-quantity manufacturing using a hybrid process including AM along with a typical composite layup process can produce satisfactory parts more efficiently than conventional reinforced sheet metal manufacturing.

Project Participants

Project Principal

Other Project Participants

- Youngstown Business Incubator (YBI)

Public Participants

- U.S. Department of Defense