News

Novel Compact Wire-fed AM Project

January 07, 2021 | Categories: Member News

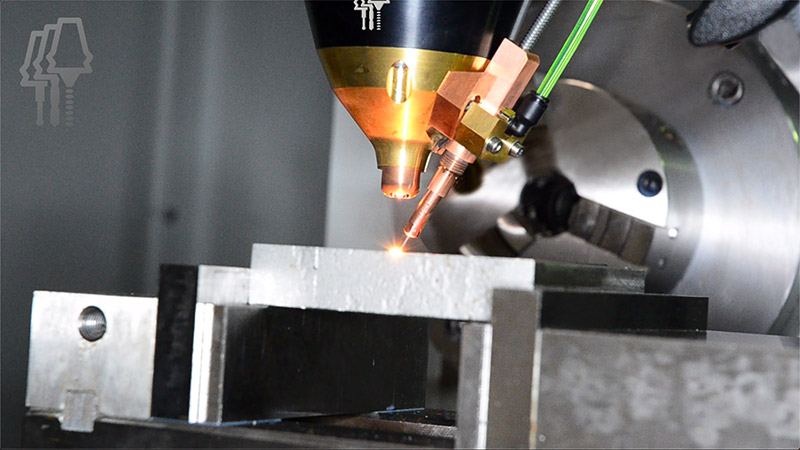

McKinney, TX, 07 January 2021- Hybrid Manufacturing Technologies (HMT) is pleased to announce their lead involvement in an InnovateUK research project entitled “Fast-track development of a novel compact wire-feed system for Laser Additive Manufacturing” (FastWireAM). This project includes collaboration with TWI and Epoch Wires. The project aims to accelerate the market uptake of HMT’s wirefed AM solution in conjunction with novel-alloy wire feedstock produced by Epoch Wires.

The main objectives of this project are to demonstrate the advantages of the HMT interchangeable head using wire feedstock over subtractive manufacturing and current state-of-the-art wire DED techniques, as well as the added value of using Epoch Wire’s powder-cored wire feedstock. This will be validated through manufacture of select industrial use-case components.

The new system will be housed at TWI’s Yorkshire, UK facility, where the new wirefeed system will be integrated with their KUKA robot cell. TWI will lead tasks relating to process optimisation and performance mapping of the system for demonstrator production and third-party validation of its performance. The FastWireAM project has received funding with thanks from InnovateUK under grant agreement No. 81046.

Hybrid Manufacturing Technologies has been a global industry leader in hybrid and additive manufacturing since 2012. Pioneering a solution to marry the freedoms of additive with the precision of CNC machining, Hybrid has developed an unprecedented line of compact interchangeable deposition and inspection heads with elegant integration methods. This extends the capabilities of the everyday CNCs and robots without compromise, accelerating the adoption of the next wave of digital manufacturing.

Courtesy of Hybrid Manufacturing Technologies